Installing Split Braided Sleeving Without Tools

2026-01-23 14:55A lot of customers are surprised when they first use split braided sleeving.

They expect to need tools, tape, or at least zip ties. In reality, most of the time you don’t need anything at all. The sleeve is already split, and the braid is flexible enough to open and close by hand.

It works on small wires, large cable bundles, and even soft hoses.

Before wrapping

If the cables are twisted, the sleeve will look messy.

So the first thing to do is simply straighten them out on the table or floor.

When you pick up the sleeve, it may look narrow. That’s normal. The braided structure is meant to stretch. With light pressure from your fingers, it will open much wider than it looks.

Putting it on

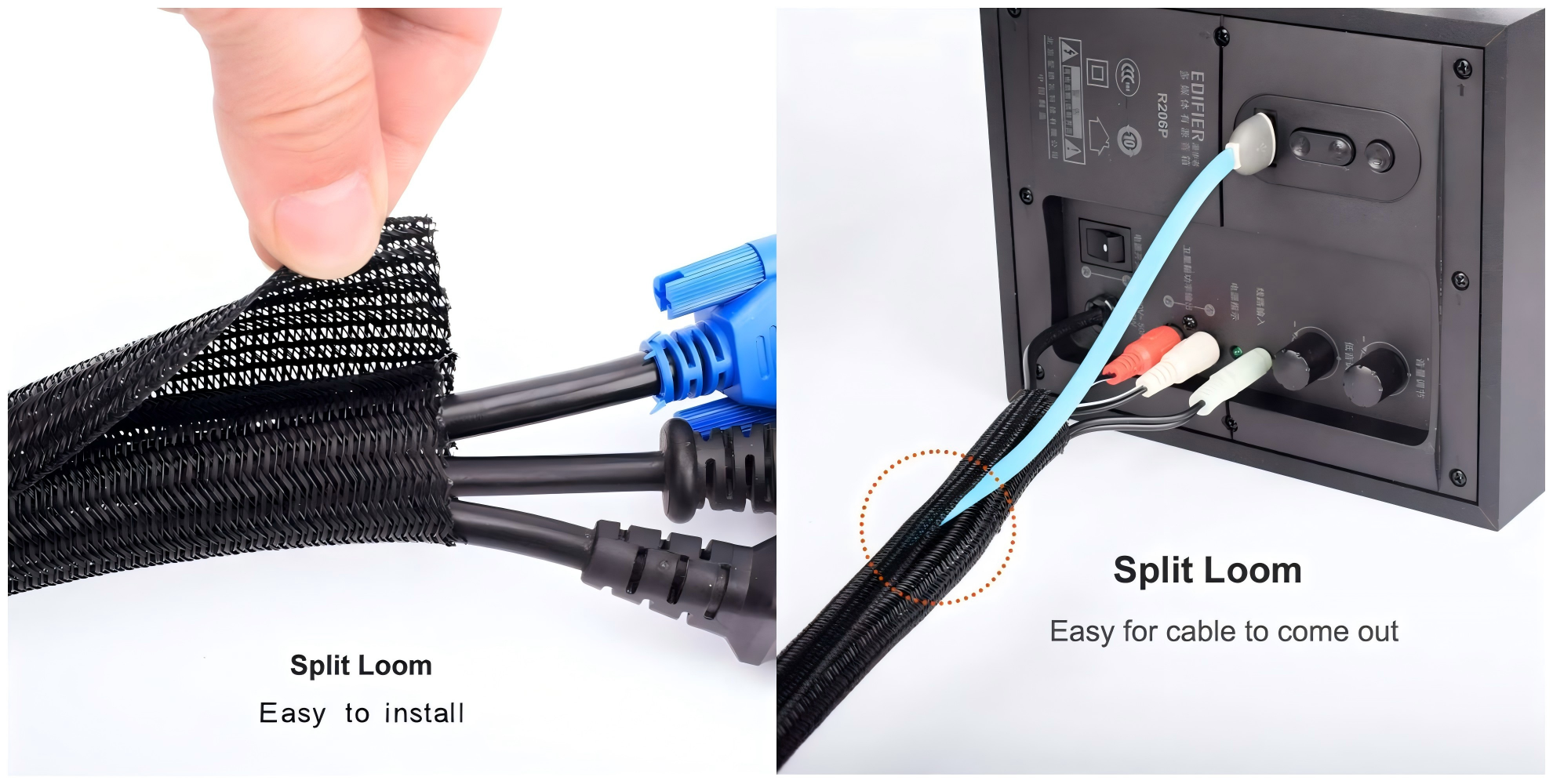

Hold the sleeve at one end and pull the split open.

You will feel the braid give way easily. It is not stiff.

Place the opened sleeve over the cables, or press the cables into the opening. Then slide your hand along the length. As you move, the split naturally closes behind your fingers and wraps itself around the cables.

You don’t have to force it. The braid does most of the work for you.

Single cables drop into place on their own.

Larger bundles just need to be held together while you wrap.

Adjusting the fit

After the sleeve is on, it may not look perfect.

Just run your hand along it once or twice. Small twists and wrinkles disappear very quickly. The braid is soft and easy to shape.

Keeping the ends from moving

In many cases, the sleeve stays where it is without anything extra.

But if you want to make sure it doesn’t slide, there are two simple ways to do it by hand.

One way is to fold a small section of the sleeve back over the cable and tuck it inside. The tension of the braid holds it.

Another way, for thicker sizes, is to squeeze the edges together and give them a slight twist around the cable. The friction is usually enough to lock it.

No ties. No tape.

If the sleeve is too long

Most split braided sleeving should be cut with scissors to get a clean, straight edge.

Hold the split braided sleeving firmly and cut across the braid. A neat cut makes the installation look better and prevents uneven ends.

After cutting, lightly pass a flame from a lighter along the cut edge.

The nylon or polyester fibers will melt slightly and seal together. This stops the braided sleeve from opening up or fraying over time.

You only need a quick touch of heat — just enough to lock the fibers in place.

Once cooled, the end stays smooth, tight, and secure on the cable.

This simple step takes less than a minute but keeps the sleeve looking clean and professional.

Things people learn after using it a few times

If a big cable bundle feels loose, using two layers gives a much tighter result.

The sleeve follows bends and curves without cutting or shaping.

And there is no need to stretch it hard — too much pulling can actually make it hold less.

Why it works this way

Split braided sleeving was designed for real work, not for tools.

The opening lets you wrap it around anything, and the braided structure grips by itself. That is why electricians, installers, and maintenance teams use it when they want something fast and reusable.

When cables change later, you simply open the split again. Nothing is damaged. Nothing is wasted.