The Ultimate Solution for Cable Management and Protection

PPS expandable braided sleeving is made from UL94V0-rated PPS material, offering high wear resistance, chemical resistance, and stability under high temperatures. It provides excellent protection for wires, cables, and pipes, with a continuous operating temperature of -70°C to +200°C. Lightweight yet durable, PPS expandable braided sleeving withstands harsh environments and most chemicals, making it ideal for demanding industrial applications. PPS expandable braided sleeving ensures long-term performance and reliability in extreme conditions.

- EKO

- China

- 7-15days

- 5000000Meters/Month

- Information

Braided Sleeving: The Ultimate Solution for Cable Management and Protection

Introduction: Why Braided Sleeving Matters

Picture this: a tangle of wires behind your desk, a chaotic bundle of cables in your car’s engine bay, or exposed wiring in an industrial setup. It’s not just unsightly—it’s a recipe for disaster. Unprotected cables face constant threats from abrasion, heat, chemicals, and vibrations, leading to premature wear, costly repairs, or even safety hazard

Enter braided sleeving, the overlooked champion of cable organization, is a flexible, sturdy, and simple-to-use solution that shields, streamlines, and prolongs the life of your cables. From household gadgets to robust industrial equipment, it delivers a polished, dependable way to maintain your wiring. Whether you're decluttering a home workspace, securing automotive cables, or even shielding a fishing rod on the go, braided sleeving transforms the task with ease.

In this guide, we’ll explore why braided sleeving is essential, its key benefits, the different types available, and how to choose the right one for your needs.

Why Choose Braided Sleeving?

Braided sleeving isn’t just about aesthetics—it’s a practical solution designed to address real-world challenges. Here’s why it’s a must-have:

Protection Against Wear and Tear: Shields cables from abrasion, cuts, and friction, especially in high-movement or high-contact environments.

Heat and Chemical Resistance: Safeguards wiring from extreme temperatures and corrosive substances, ensuring reliability in harsh conditions.

Cable Organization: Bundles multiple cables into a single, neat package, reducing clutter and improving accessibility.

Noise Reduction: Minimizes rattling or vibration noise from loose cable bundles, ideal for automotive or industrial settings.

Extended Cable Lifespan: By reducing stress and damage, sleeving helps cables last longer, saving you time and money on replacements.

Aesthetic Appeal: Creates a clean, professional look for home, office, or industrial setups.

Where Is Braided Sleeving Used?

Braided sleeving is incredibly versatile, with applications across industries and hobbies:

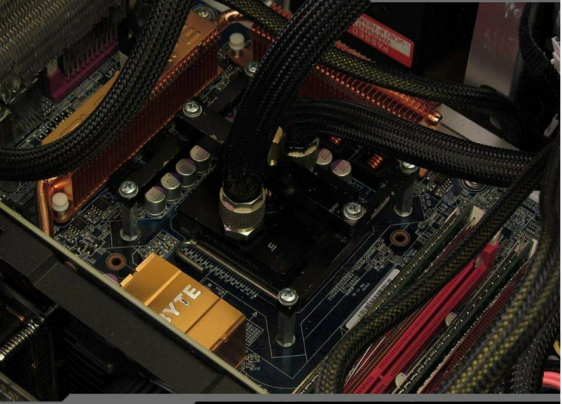

Automotive and Motorcycle: Protects wiring harnesses from heat, oil, and vibrations in engine bays or undercarriages.

Home and Office: Organizes cables for computers, entertainment systems, or furniture wiring, reducing clutter and hazards.

Industrial Machinery: Shields cables in factories, protecting against abrasion, chemicals, and heavy wear.

Aerospace and Electronics: Ensures reliable performance in high-stakes environments with extreme conditions.

Outdoor and Recreational: Used as protective sleeves for fishing rods, camping gear, or marine equipment during storage and transport.

Types of Braided Sleeving and Their Applications

Braided sleeving comes in various materials, each tailored to specific needs. Below, we dive into the three most popular types, their features, and where they shine.

1. PET Braided Sleeving

Material: Polyethylene Terephthalate (PET)

Best For: General-purpose cable management and protection.

Features:

Excellent abrasion resistance for everyday wear.

Wide temperature tolerance (-50°C to 150°C).

Lightweight, flexible, and expandable for easy installation.

Cost-effective and available in various colors for aesthetic customization.

UV-resistant for outdoor use

Applications:

Home Electronics: Perfect for organizing TV, gaming console, or computer cables.

Data Centers: Keeps server wiring tidy and protected from dust and abrasion.

Furniture Wiring: Hides and protects cables running through desks or entertainment units.

Fishing Rod Sleeves: Protects rods from scratches and tangles during transport.

Pro Tip: Choose PET sleeving with a tight weave for better coverage or a looser weave for maximum flexibility, depending on your project.

2. PPS Expandable Sleeving

Material: Polyphenylene Sulfide (PPS)

Best For: High-temperature and chemically harsh environments.

Features:

Exceptional heat resistance (up to 200°C or higher).

Superior chemical stability against oils, solvents, and acids.

Flame-retardant, meeting stringent safety standards (e.g., UL94 V-0).

Durable yet lightweight for demanding applications.

Applications

Engine Bays: Protects automotive or motorcycle wiring from extreme heat and oil exposure.

Industrial Ovens: Shields cables in high-heat manufacturing processes.

Chemical Processing Plants: Resists corrosion from harsh chemicals.

Aerospace: Ensures reliable wiring in high-temperature avionics systems

Pro Tip: Pair PPS sleeving with heat-resistant cable ties for secure bundling in extreme conditions.

3. Nylon Expandable Sleeving

Material: Nylon 6.6

Best For: Heavy-duty applications requiring maximum durability.

Features

Unmatched abrasion resistance for high-wear environments.

High tensile strength and flexibility for frequent cable movement.

Resistant to UV, moisture, and mildew.

Available in tight or loose weaves for varying levels of protection and flexibility.

Applications:

Automotive Harnesses: Protects wiring in vehicles subject to constant vibration and friction.

Robotic Arms: Shields cables in automated machinery with repetitive motion.

Marine Equipment: Resists moisture and wear in boats or docks.

Heavy Machinery: Ensures long-lasting cable protection in construction or mining equipment.

4. PET Split Braided Sleeving

Material: PET with a longitudinal split design

Best for: Retrofitting existing cable setups.

Features: Wrap-around style, easy installation, allows midline insertion.

Applications: IT racks, cable upgrades, areas where disconnecting wires isn’t feasible.

5. Fishing Rod Sleeve (PET-based)

Material: PET (similar to standard PET braided sleeve)

Best for: Rod protection and tangle prevention.

Features: Lightweight, breathable, protects rod finish.

Applications: Fishing gear storage and transport.

How to Use Braided Sleeving

Installation Methods:

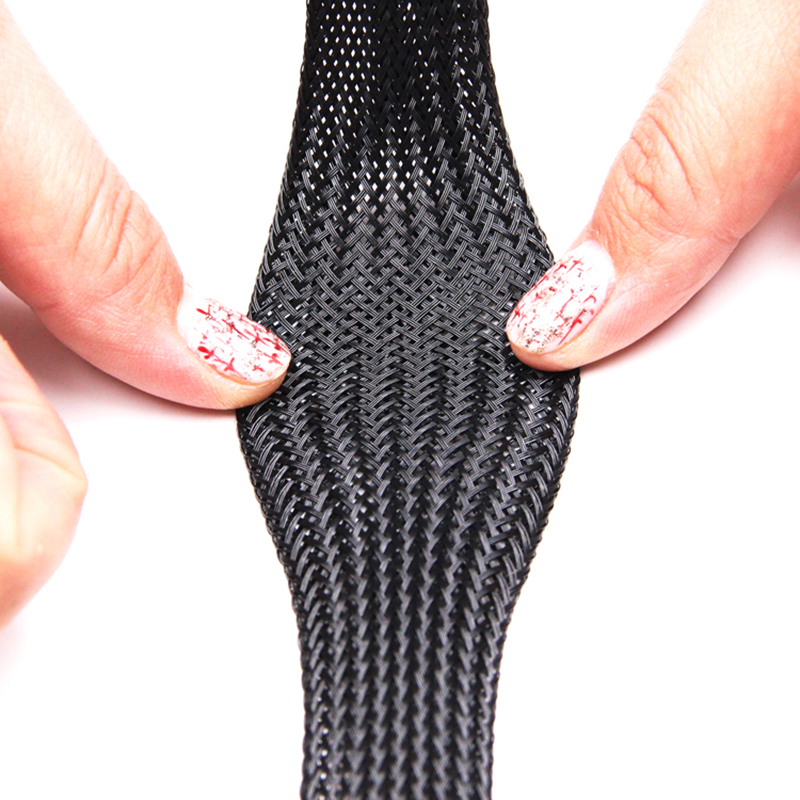

Expandable Sleeving: Push cables through the sleeve; it expands and contracts to grip the bundle

Split Sleeving: Wrap the sleeve around existing cables and secure it with Velcro, tape, or heat shrink.

Fishing Rod Sleeves: Slide over rod tips and let the mesh conform to the shape.

Tips for Smooth Installation:

Use a feeding tool or electrical tape on the cable tip to ease insertion.

Secure ends with heat shrink tubing or clamps for a neat finish.

Bundle cables before sleeving to simplify routing.

How to Cut Braided Sleeving

Fraying can be a challenge with braided products. Here’s how to prevent it:

Best Method: Hot Knife

Cuts and seals in one go.

Recommended for frequent use or professional jobs.

Alternative: Sharp Scissors + Heat Shrink

Cut with sharp scissors.

Seal the ends with heat shrink tubing or a quick pass of a lighter flame to melt the fibers.

For Split Sleeving:

Fraying is less of an issue.

Cut to length and secure ends using cable ties or heat shrink.

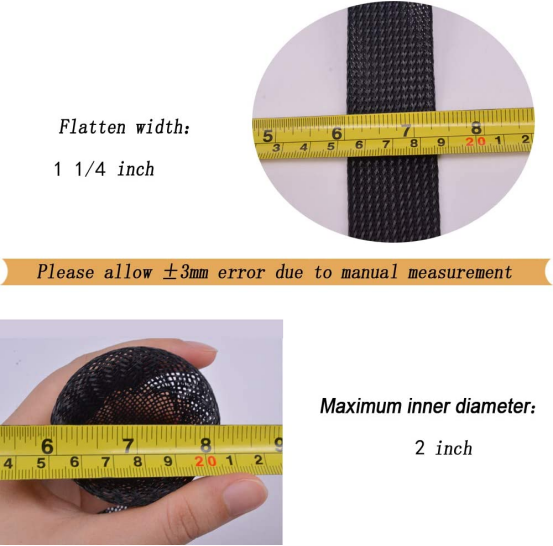

How to Measure Braided Sleeving

Choosing the right diameter ensures a snug, professional-looking fit.

Step-by-Step:

Gather your cable bundle fully.

Measure the outer diameter using a caliper or measuring tape.

Choose a sleeving range that includes your bundle diameter.Example: If your bundle is 12mm, choose a sleeve that expands 10–16mm.

Account for expansion: Expandable sleeving stretches 1.5x–2.5x its flat diameter.

Pro Tip: Always go slightly larger if you're uncertain — you can tighten the fit later.

From standard PET sleeves for general use to PPS for extreme heat or nylon for heavy-duty abrasion resistance, braided sleeving comes in many forms. If you’re wrapping up a retrofit project, PET split sleeving is a time-saver. And don’t forget, it’s even great for niche needs like fishing rod protection.

With decades of experience in cable protection, we understand that not all sleeving is created equal. Material choice, sleeve type, and correct sizing matter — and we’re here to help you get it right.

Whether you’re in the tech industry, automotive sector, industrial design, or just tired of the mess under your desk — braided sleeving is a smart, affordable solution to protect what powers your world.

Where to Buy Braided Cable Sleeves?

Official website: https://www.xmqxsm.com

Amazon: A wide selection of braided cable sleeves in various sizes and colors. Pls click the link: https://www.amazon.com

BtoB Web: Good for bulk purchases, especially if you're looking for specific types or sizes. Pls click the link: https://xmqixing.en.alibaba.com/ and https://www.made-in-china.com

Conclusion: Find the Right Fit for Your Cable Protection Needs

Selecting the right braided sleeving comes down to understanding your specific project requirements—whether it’s exposure to heat, abrasion, movement, or chemical resistance. Each sleeving type—PET, PPS, Nylon, or split design—offers distinct advantages to help you organize and protect your cables with confidence.

No matter the application—electronics, automotive, industrial machinery, or even outdoor gear—braided sleeving is a smart, durable, and cost-effective cable management solution.

Still have questions?

We hope this guide gave you a solid foundation on braided cable sleeves. If you need personalized advice or help choosing the best option, EKO is here to assist. We offer a full range of braided sleeving and packaging solutions tailored to your needs.

Contact us today for expert guidance or to request product samples.