Why Heat Shrink Tube Is Your Go-To Solution for Lasting Cable Protection

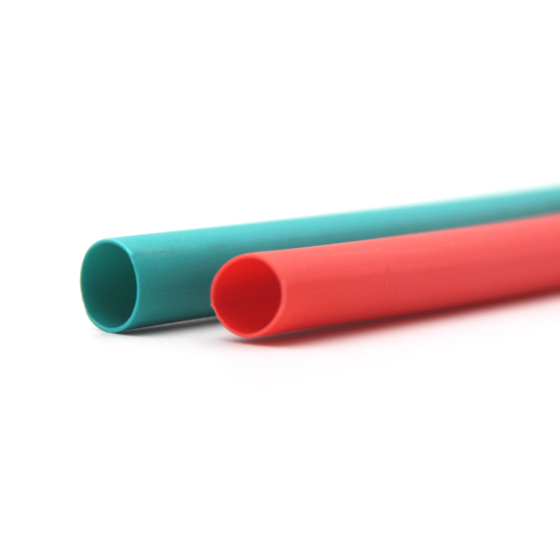

This Heat-shrink Tube offers excellent insulation, waterproofing, and abrasion resistance. Easy to use and evenly shrinking, it’s ideal for wire protection and sealing in industrial and electronic applications.

- EKO

- China

- 15-20 days

- 3000000 meters per month

- Information

Why Heat Shrink Tube Is Your Go-To Solution for Lasting Cable Protection

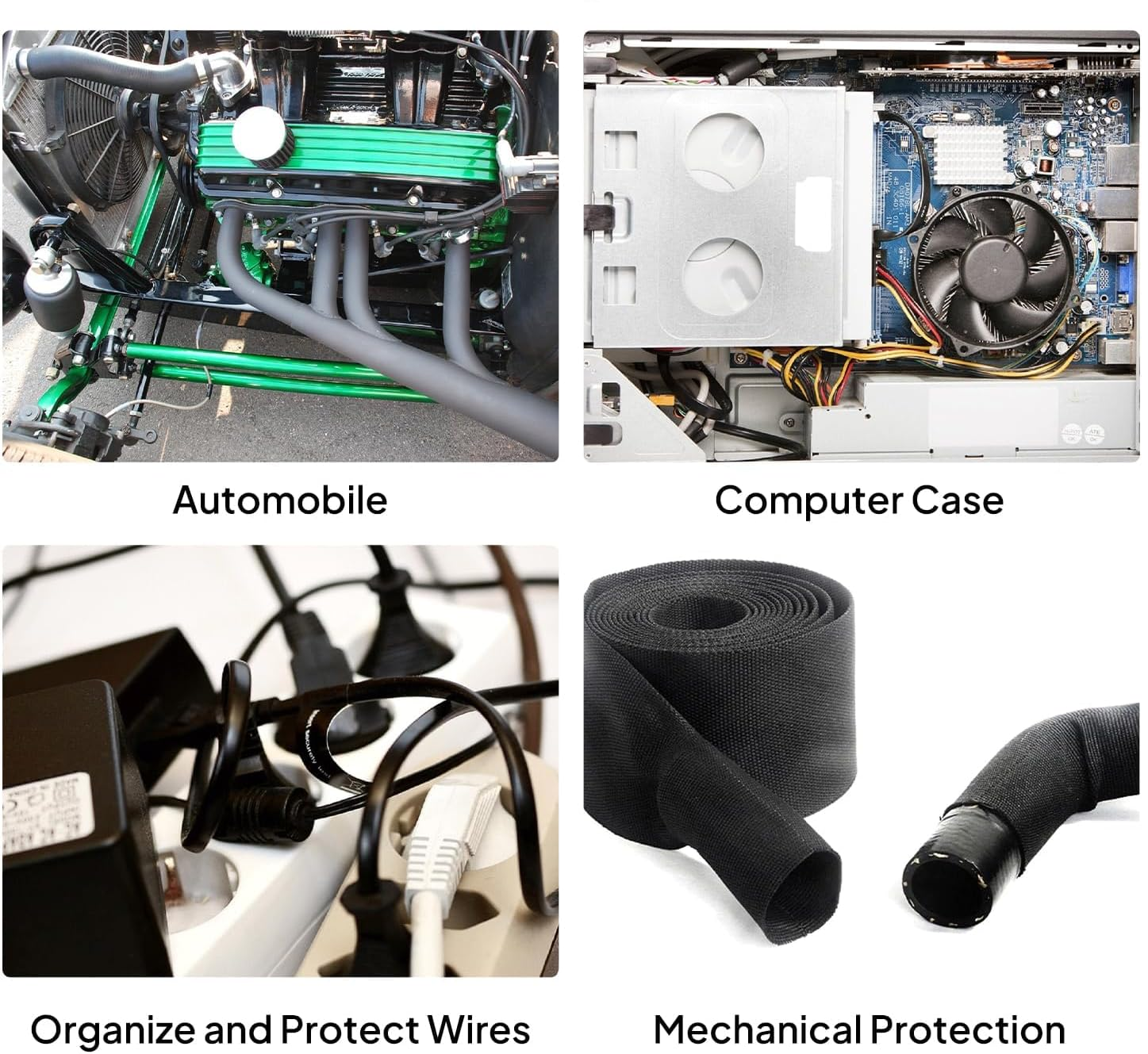

Whether you’re repairing a frayed charger cable, building an automotive wiring harness, or sealing marine electronics against salt spray, heat shrink tube delivers a simple yet powerful way to insulate, bundle, and protect your wires. These tubes shrink uniformly when you apply heat—snugging up around splices, terminals, and assemblies to form a durable, protective barrier.

Why Heat Shrink Tube Matters

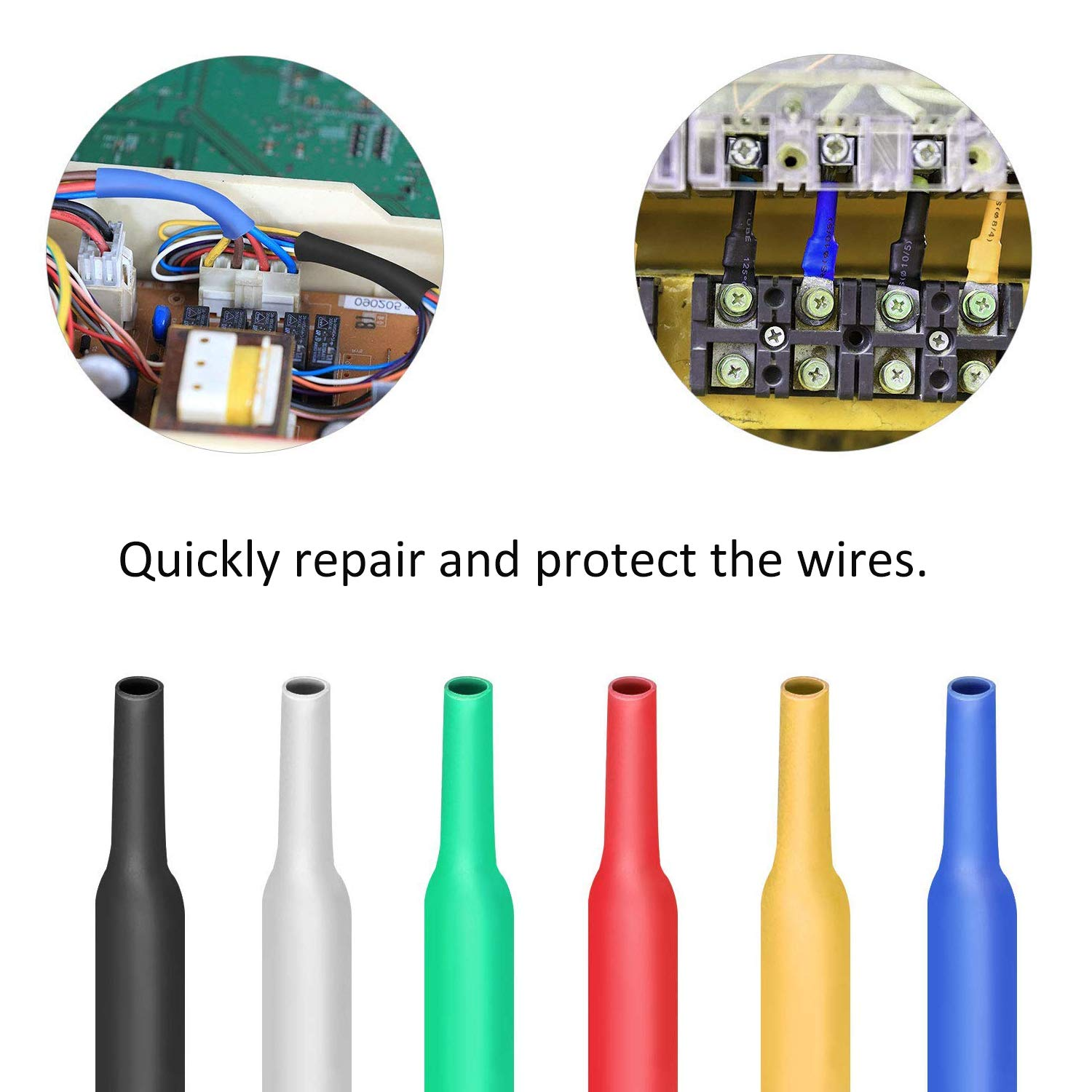

1. Insulation Protection: Ensuring Safety

Heat shrink tubing effectively prevents short circuits and leakage currents by covering exposed wires and isolating electrical currents, thereby avoiding the risks of short circuits or electric shocks caused by contact between conductors. Additionally, certain types of heat shrink tubing are made from specialized materials that provide high-voltage resistance, making them essential for power systems and industrial equipment operating in demanding environments.

2. Mechanical Protection: Extending Equipment Lifespan

Heat shrink tubing provides excellent abrasion and tear resistance, protecting cables from damage caused by friction, vibration, and mechanical stress while outperforming traditional electrical tape in durability - making it ideal for demanding applications like automotive wiring harnesses and moving parts.

3. Sealing and Moisture Resistance: Withstanding Harsh Environments

Heat shrink tubing provides waterproof and corrosion-resistant protection by forming an airtight seal when shrunk, effectively blocking moisture, dust, and chemicals. This makes it ideal for outdoor applications like solar panel connections, marine electrical systems, and protecting battery terminals from oxidation in harsh environments.

4. Environmental Durability: Adapting to Extreme Conditions

Heat shrink tubing offers exceptional environmental protection with its waterproof, corrosion-resistant sealing that blocks moisture, dust and chemicals - ideal for solar panels, marine systems and battery terminals. For extreme conditions, specialized variants provide high-temperature resistance (over 125°C for engine bays) and chemical resistance against oils, solvents and acids, making them indispensable for chemical plants and laboratory applications.

5. Easy Installation: Saving Time and Effort

Heat shrink tubing offers fast and easy installation—simply apply heat (from a heat gun or similar tool) for rapid shrinking. Once heated, it tightly conforms to any shape, seamlessly fitting around connectors, solder joints, and uneven surfaces for a secure, professional finish. This quick and adaptable application makes it ideal for both simple repairs and complex wiring projects.

What types of heat shrink tubing are there?

1. PE heat shrink tube

PE heat shrink tubing prevents shorts and leakage while resisting abrasion, moisture, and extreme heat. Whether sealing battery terminals or protecting industrial harnesses, it delivers durable, cost-effective protection for everyday application.

2. Dual wall Heat-shrink Tube

Every conductor needs a dependable dielectric layer. Dual wall Heat-shrink Tube resists voltage breakdown and prevents shorts in crowded panels. Whether you’re working on AC mains or low-voltage signal lines, you’ll rely on consistent, long-term insulation.

3. Non-slip Heat Shrink Tube features a slightly textured finish that grips cables, preventing slippage in high-vibration environments—ideal for automotive engine bays or industrial robots.

4. Busbar Heat Shrink Tube is formulated to withstand physical knocks and abrasion, making it perfect for heavy-duty power distribution blocks and busbar assemblies.

5. Fabric heat shrink tube has a unique material compared to other heat-shrinking sleeves. It is made by weaving polyester fibers and polyolefin monofilaments together. It has excellent noise reduction performance, flexibility, wear resistance and heat insulation properties. Some irregularly shaped wires and hoses have been widely used. For example, drilling machinery, hydraulic pipelines, etc.

6. Teflon Heat Shrink Tube offers exceptional chemical inertness and can handle corrosive acids and bases—ideal when you need a seal that stands up to harsh lab or industrial chemicals.

Our Technical Edge

From everyday DIY fixes to mission-critical wiring in aerospace and marine environments, heat shrink tube stands out as a versatile, cost-effective protection method. By choosing the right product—Dull Wall Heat-shrink Tube, Busbar Heat Shrink Tube, Non-slip Heat Shrink Tube, Silicone Heat Shrinkable Tube, or PTFE Heat Shrink Tube—you’re investing in safe, reliable performance. At [Your Company Name], our rigorous manufacturing and testing ensure that every meter you cut delivers the insulation, durability, and precision your projects demand. Empower your cables with heat shrink tube and enjoy peace of mind today.

Conclusion

From everyday DIY fixes to mission-critical wiring in aerospace and marine environments, heat shrink tube stands out as a versatile, cost-effective protection method. By choosing the right product— PE Heat Shrink Tube, Dull Wall Heat-shrink Tube, Busbar Heat Shrink Tube, Non-slip Heat Shrink Tube, Fabric Heat Shrinkable Tube, or PTFE Heat Shrink Tube—you’re investing in safe, reliable performance. At Xiamen QX, our rigorous manufacturing and testing ensure that every meter you cut delivers the insulation, durability, and precision your projects demand. Empower your cables with heat shrink tube and enjoy peace of mind today.

FAQs: What You Really Want to Know

How do I pick the right size?

Measure your cable bundle’s maximum diameter, then choose tubing with an initial ID about 10–20% larger. Check the shrink ratio to ensure a snug final fit.

Will it stick permanently?

Standard single-wall tubing does not adhere—but dual-wall variants with an inner adhesive lining form a waterproof seal when you heat them.

Can I use it on irregular shapes?

Yes. Fabric Heat Shrinkable Tube is flexible enough to conform around connectors, sensors, and even small PCBs.

What heat source should I use?

A heat gun set between 120 °C and 200 °C works best. Avoid open flames to prevent scorching or overheating. Different products have different requirements for heating temperature. Please consult us for specific circumstances.

Is it reusable if removed?

Generally no—once shrunk, the polymer sets in its memory shape. For reusable bundling, consider Spiral Wrap or cable ties instead.

We have various heat shrink tubes that can meet the needs of different industries. If you have any further questions, please feel free to contact us at any time. We will provide you with a professional solution.

About us