Cable sleeve buyer’s guide 2026: fireproof, braided or insulated — which one do you need?

2026-02-05 18:362026 is here, and with it comes the fast development of smart infrastructure, the rise of new energy, and smarter industrial work. And all these changes have made cable protection sleeves much more in demand. But the market is flooded with so many different types-so how should us choose cable sleeves that actually meet our need, without overspending or skimping on safety?

Here is a 2026 ultimate buyer’s guide takes the guesswork out of confusing industry terms, clearly lays out how fire-resistant, braided, and cable insulation sleeve differ from one another, and provides an easy-to-follow plan to help you choose the right fit.

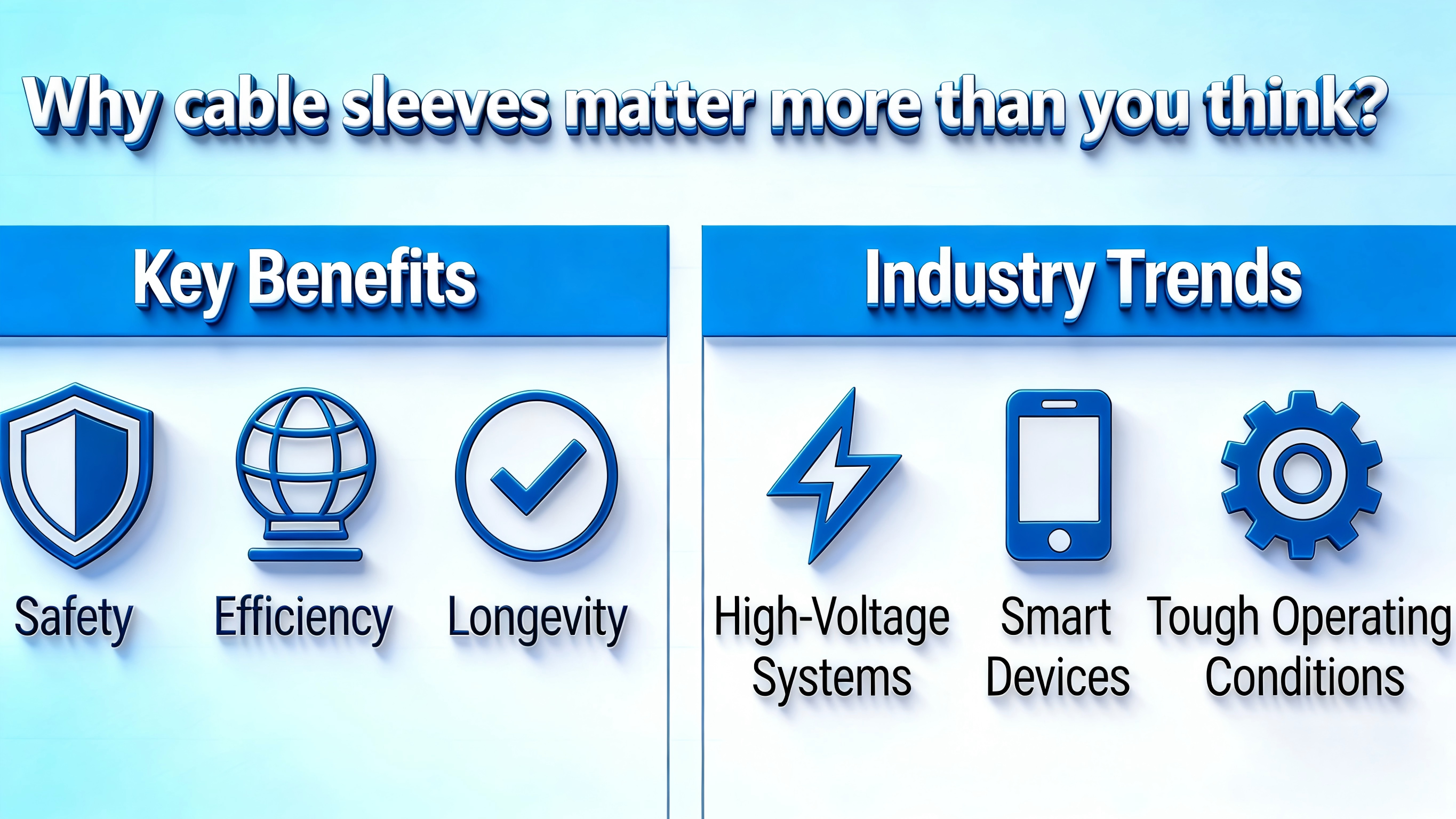

Why cable sleeves matter more than you think?

Choosing the right cable sleeve isn’t just about protection-it’s about future-proofing your projects.

The period that cable sleeves were just “optional extras”are gone. Nowadays, cable sleeving is much more important in safety, efficiency, and longevity-especially as industries move toward high-voltage systems, smart devices, and tough operating conditions, clearly lays out how fire-resistant, braided, and insulated cable sleeves differ from one another, and provides an easy-to-follow plan to help you choose the right fit. Let’s get into the details!

Fireproof cable sleeves: your first line of defense against flames

Think of fireproof sleeves as a “fireproof coat” for your cables. Made from high-performance materials like fiberglass, silicone, or meta-aramid, they’re engineered to withstand extreme heat, prevent flame spread, and even protect cables from molten metal splatters. Besides hook &loop fire sleeve and spiral fire sleeve are also good choices.

Key advantages :

- Withstands high temperatures and fire proof-perfect for high-heat zones like foundries or engine bays .

- Flame-retardant which is made of fiberglass-meets global safety standards .

Who needs it?

• Industrial facilities (steel mills, chemical plants, power stations) where high temperatures or open flames are present .

• Commercial buildings (hospitals, malls, data centers) where fire safety is non-negotiable.

• EV and aerospace industries–protects battery cables and wiring from thermal runaway .

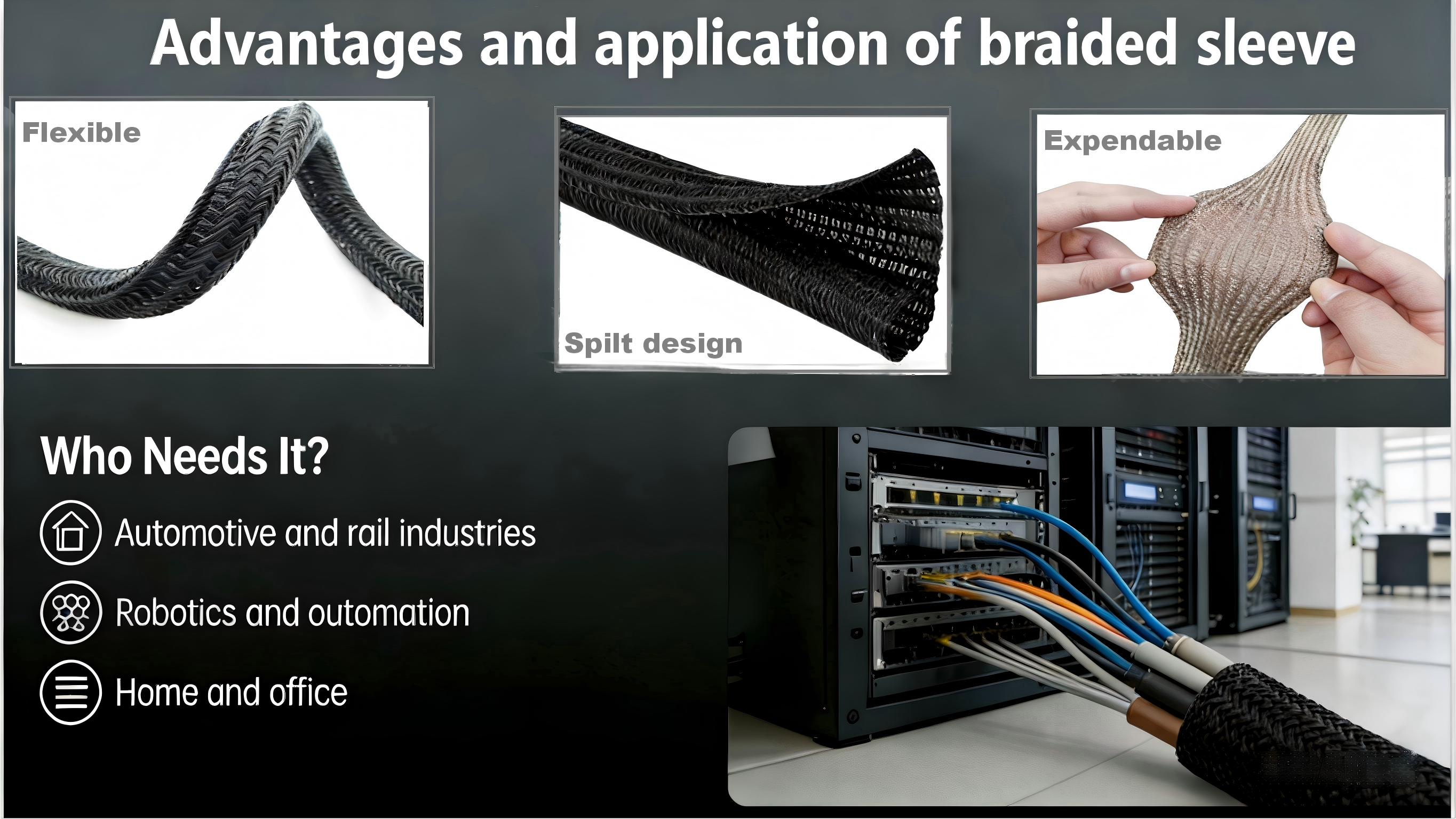

Braided cable sleeves: the flexible workhorse for mechanical protection

Braided sleeves are like “chainmail” for your cables-braided from polyester, polyamide, or tinned copper to balance flexibility and durability. Their open and closed design, which meet different needs. And expandable structure makes them ideal for bundling wires and protecting against abrasion, friction, and impact .

Key advantages :

- Ultra-flexible–bends 90°+ without cracking, perfect for tight spaces and moving parts (robots, automotive wiring harnesses) .

- Expandable design- fits bundles of varying sizes ,some even expend more than 1.5 times (saves you from buying multiple sleeve sizes) .

- New EMI-shielding variants (tinned copper braid)-blocks electromagnetic interference for sensitive electronics .

Who needs it?

• Automotive and rail industries-protects wiring from vibration and friction .

• Robotics and automation-handles constant bending and movement .

• Home and office-organizes messy cables (TV setups, server racks) with a clean, professional look .

Insulated cable sleeves: the essential for electrical safety

Insulated sleeves are the “insulating blanket” for your cables—designed to prevent electrical leakage, short circuits, and shock hazards. Made from materials like polyolefin, PVC, or PTFE, they’re all about maintaining electrical integrity in diverse environments .

Key advantages :

- High dielectric strength- up to 20kV/mm (PTFE variants) for high-voltage applications .

- Wide temperature range -from -65°C to 260°C (fluor variants)- works in extreme cold or heat .

- Waterproof options (double-wall with hot-melt adhesive)-seals out moisture in damp environments (underground, marine) .

Who needs it?

• Electrical contractors -for wire splices, terminations, and low/high-voltage cables .

• Marine and offshore industries -resists saltwater corrosion and moisture .

• Consumer electronics -protects delicate wiring in phones, laptops, and appliances.

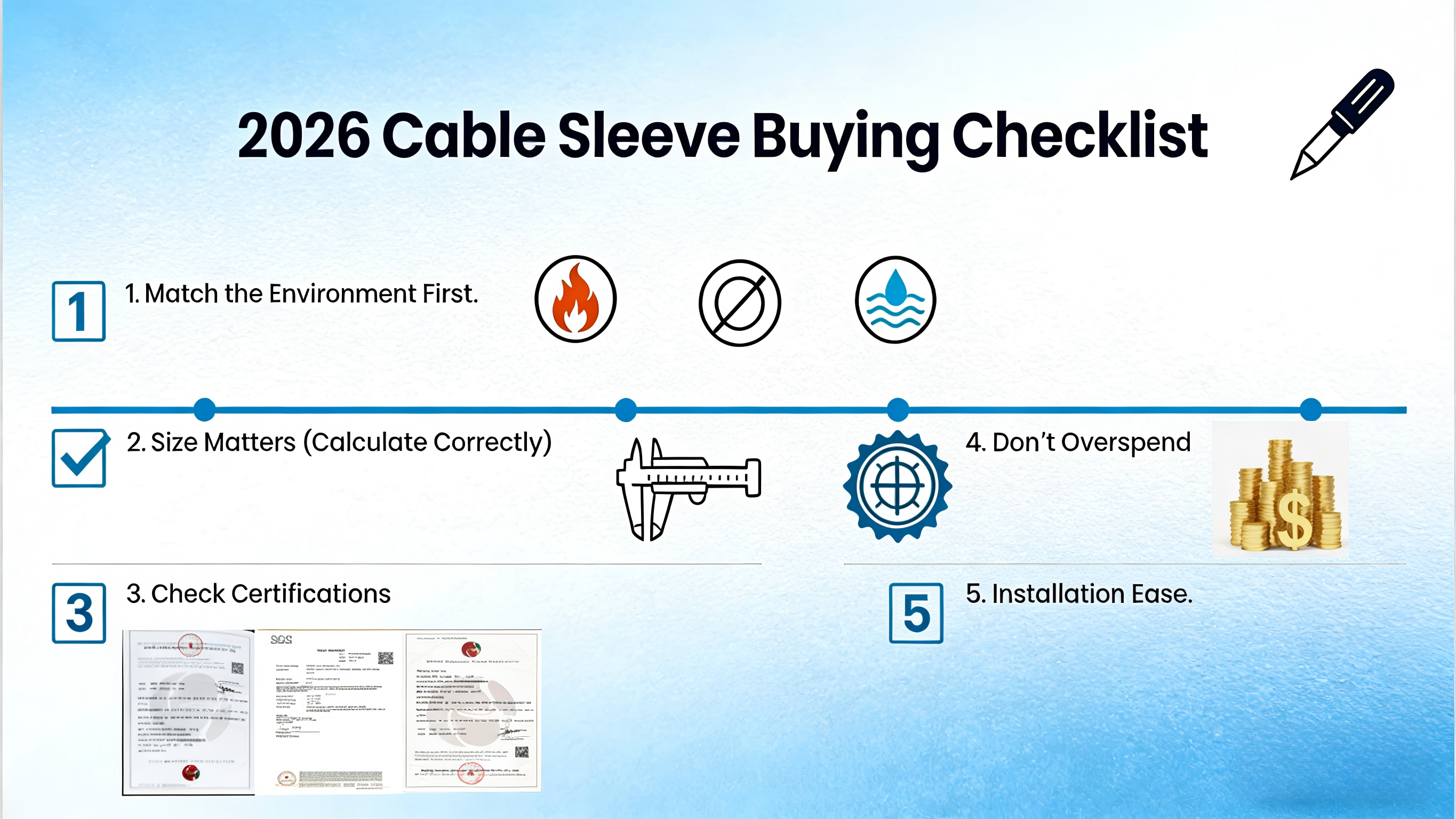

Cable sleeve buying checklist: avoid these costly mistakes

Even the best cable sleeve won’t work if you pick the wrong size or material. Use this checklist to avoid common pitfalls and save money!

1. Match the Environment First: High heat? Go fireproof. Constant movement? Braided. Damp or high-voltage? Insulated .

2. Size Matters (Calculate Correctly): For heat-shrink sleeves, choose a pre-shrink diameter≥ 1.5x your cable diameter, and a post-shrink diameter ≤ 0.8x your cable diameter . For braided sleeves, pick a size that’s 10-20% smaller than your bundle (they expand!).

3. Check Certifications: Look for UL, RoHS, or ISO certifications—non-certified sleeves may fail safety tests .

4. Don’t Overspend: you don’t need a fireproof sleeve for a home TV setup—braided sleeves work just fine. Save premium materials for high-risk areas.

5. Installation Ease: For existing cables, choose wrap-around braided or snap-on fireproof sleeves (no wire cutting required) .

Final Verdict: Which Sleeve Is Right for You?

• Fireproof: for high-heat, high-risk environments (industrial, commercial, EV) – safety first.

•Braided: for flexibility, organization, and mechanical protection (automotive, robotics, home/office) – versatility wins.

•Insulated: for electrical safety, moisture resistance, and high-voltage (electrical, marine, electronics) – integrity is key.

Remember: In 2026, the best cable sleeve isn’t the most expensive one—it’s the one that fits your specific needs. Whether you’re upgrading your industrial setup, building an EV, or just tidying up your home office, the right cable sleeve will save you time, money, and headaches down the line.