Application of Cable sleeving in Car

2020-10-09 15:12Car safety is a issue that we all pay attention to, the car manufacturers also put the Car safety in the top priority. With the development of cars, there are seat belts, airbags and even active safety systems. But few people pay much attention to the protection of car wiring harnesses. Now more and more electric appliances in cars, along with the bus circuit is also more and more complex, which exists hidden trouble almost people ignore.

Automobile wiring harness is the main body of network transmission of automobile circuit. It connects the electric and electronic parts of automobile and makes them function. If the wiring harness is damaged lightly, the corresponding function fails; if it is severely damaged, it may cause short circuit and spontaneous combustion. So the protection of wire harness is essential.

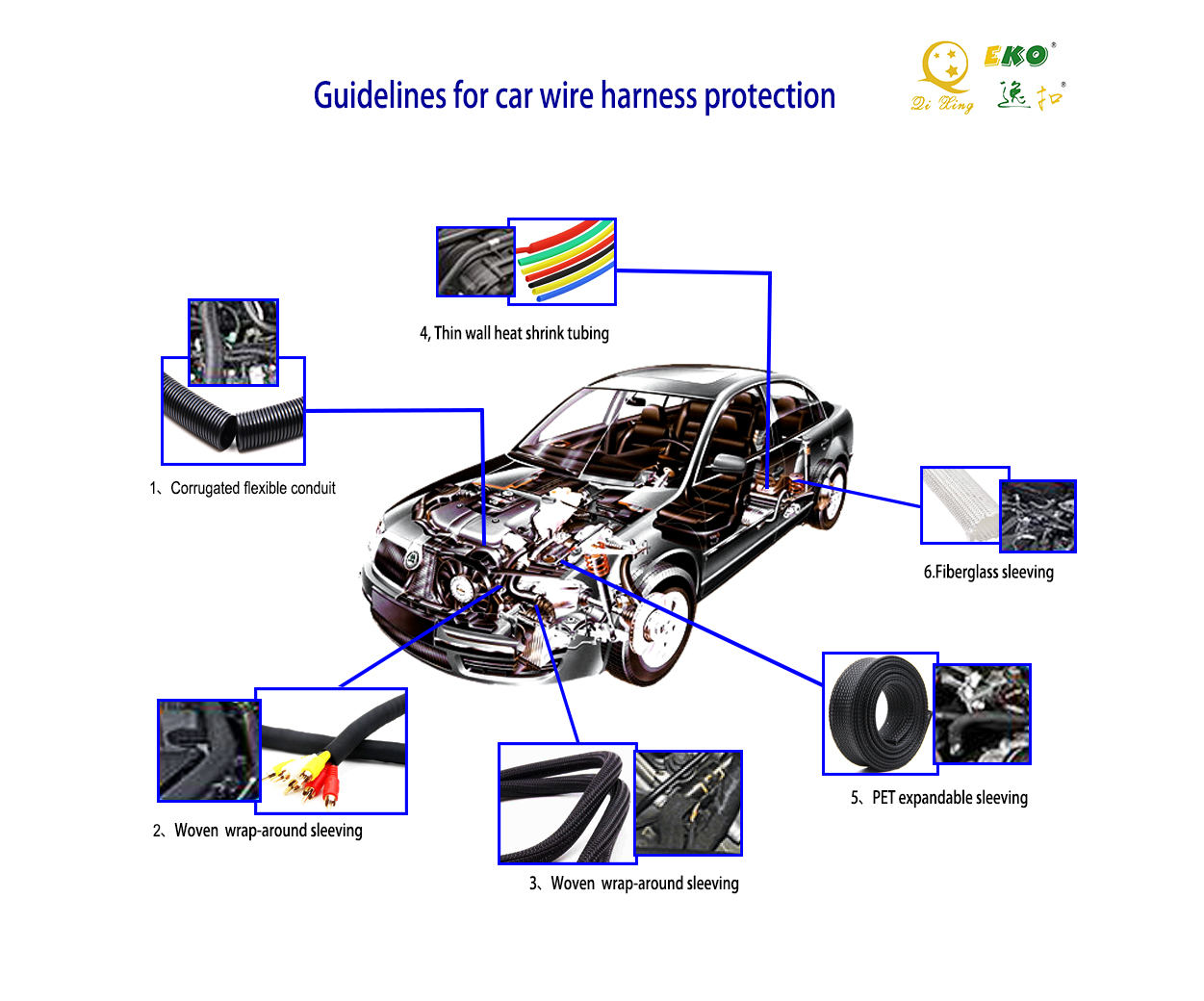

The protective sleeves like as corrugated tube, nylon /PET braided expandable wire sleeve, nylon protective sleeve, heat-shrinkable tube, self-winding protective sleeve,etc. which mainly play the role of wrapping fixation, wear resistance, flame retardant, insulation, corrosion resistance, and anti-electric wave interference. Let’s show you what they are.

Corrugated tube

The material of the Corrugated tube are PA, PP and PE. Its main characteristics are good wear resistance, high temperature resistance up to 150℃, flexibility, and good anti-distortion performance. As their excellent wear resistance, flame retardant, high temperature performance, it usually used in the engine compartment and the floor section.

Nylon /PET braided expandable wire sleeve

This kind of cable protective sleeve is flame-retardant and halogen-free. As its strong scalability and extensibility, it offers durable abrasion resistance in wide range of Automobile industrial applications.

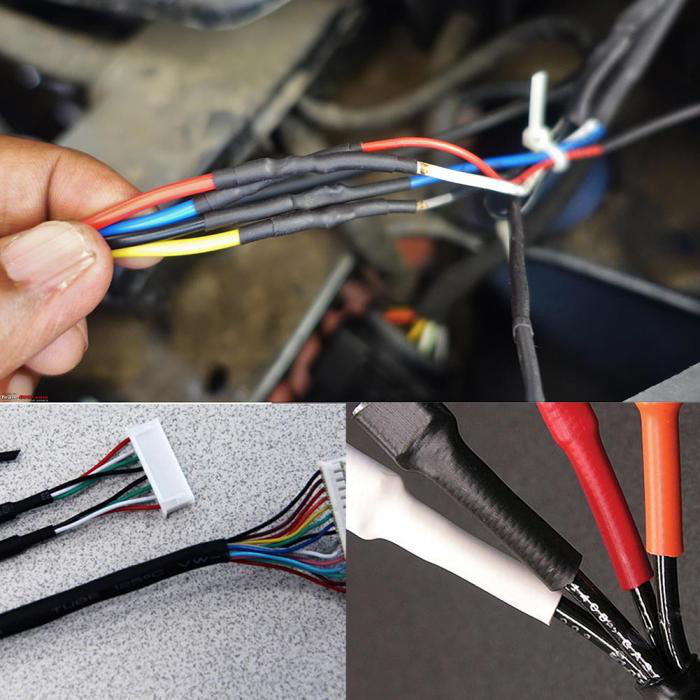

Heat shrink tube

Heat shrinkable tube not only has the high temperature shrinkage characteristic and good sealing, but also has the anti-corrosion ability. Mainly used for wire junction and wire harness plug protection, focusing on sealing waterproof and anti-corrosion oxidation.

A large part of the wiring harness in the engine compartment of a car is located around the engine. There are many sensors, and it is necessary to consider both fixation and harsh environment, waterproof, heat insulation, vibration and other aspects.

In the selection of wire harness casing, it is necessary to choose high quality, high temperature resistant, anti-corrosion and anti-oxidation casing, such as Corrugated tube, self-winding protective sleeve, nylon protective sleeve, etc. Beyond this, there are wiring harness wiring of the interior, wiring harness wiring of the ceiling, wiring harness on the door, etc., they also need to cable sleeve to protection.