Beyond Abrasion: How Shielding Sleev Solves Your Toughest Wiring Challenges

2025-07-11 15:24Beyond Abrasion: How Shielding Sleev Solves Your Toughest Wiring Challenges

Introduction

Ordinary braided tubing does a great job organizing cables and protecting against wear and tear from daily use. But what if you encounter challenges beyond the norm? For example, handling sensitive data signal lines that are susceptible to electronic interference, or eliminating squeaking noises from hoses in high-vibration environments. In the face of these advanced requirements, conventional tubing is inadequate, and shielded tubing is needed to help. It is the existence of shielded tubing that provides them with a higher level of protection.

What Makes Sleeving "Shielded"? It's All in the Hybrid Design

Shielding sleeves are not a single product category, but a class of cutting-edge solutions derived from innovative engineering. As a manufacturer, we develop composite sleeves with unique and precise functions by integrating multiple materials and innovative designs. These sleeves not only provide physical protection, but also provide shielding, noise reduction, sealing and fixing functions that are difficult to achieve with standard materials. Next, we will take two typical cases as examples to deeply analyze our professional problem-solving capabilities.

The EMI Challenge: Creating a Fortress for Your Data

Background:

In today's society, our environment is full of electromagnetic interference (EMI) and radio frequency interference (RFI). These electronic noises generated by power lines, motors and other electronic devices can not only cause data corruption and signal quality degradation, but also cause sensitive equipment failures.

Engineering solution: hook and loop shielding sleeve

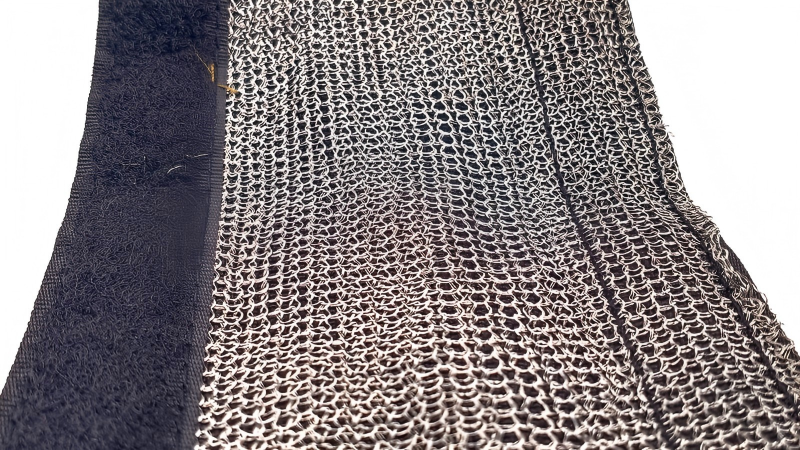

To deal with this invisible threat, we have developed hook and loop shielding sleeves - it is like a cable armor with its own "protective force field". The sleeve adopts a double-layer structure design: the outer layer is made of wear-resistant and resistant braided material, and the inner layer is embedded with a tinned copper fiber braid. This layer of conductive metal material forms a shielding structure similar to a "Faraday cage" around the cable, which can effectively block EMI/RFI signals and guide them to the ground terminal to prevent interference from affecting the delicate cables inside.

What's more, our technical advantages are not limited to shielding functions. Considering that high-tech cables often need to be integrated into complex systems, we have specially integrated high-quality hook and loop designs. This side-entry installation structure does not require the removal of any connectors, making the sleeve installation particularly convenient. The hook and loop shielding design not only provides top-level electromagnetic protection, but also achieves a practical breakthrough of "installation without disassembling the system", fully demonstrating our profound experience in creating high-performance and highly applicable solutions.

"Zipper, no interference" - Cable shielding in data centers

Problem scenario:

In many communications operations or processes, it is necessary to uniformly wire high-speed data cables between multiple cabinets, while ensuring that EMI electromagnetic interference is effectively suppressed to avoid signal attenuation; the cable maintenance is convenient to avoid repeated disassembly of the connector during maintenance; the project wiring speed is fast and the construction period is short.

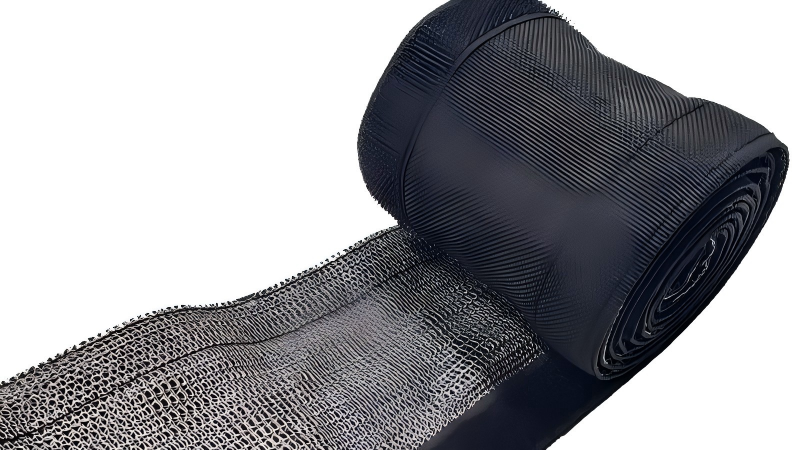

Engineering solution: zipper shielding sleeve

In response to this complex problem, the engineering team selected our zipper shielding sleeve for cable bundling and protection. The inner layer of the zipper sleeve uses a tinned copper braided mesh to effectively isolate high-frequency signal interference; the zipper structure design allows the sleeve to be quickly opened and closed, and later maintenance only requires unzipping to remove or add cables without powering off or removing the wire ends; compared with traditional metal braided shielding nets, the zipper structure significantly improves the construction speed, which is particularly suitable for use in communication projects with frequent changes at multiple points.

Your Questions, Answered

If you run sensitive data lines in parallel with power lines, or experience inexplicable signal loss or device failure in high-power environments, our hook-and-loop shielding sleeves and zipper shielding sleeves may be the answer.

About the reliability of hook-and-loop shielding sleeves:

Will the hook and loop accidentally loosen? Don't worry. We use high-quality, strong hook and loop materials that can stay locked even in harsh environments, fundamentally ensuring that the integrity of the EMI shielding function is not affected.

About the ease of use of zipper shielding sleeves:

Is the operation of zipper shielding sleeves complicated? Not at all. As long as you are proficient in zipping, you can easily master it. The sleeve slides smoothly and the protection of the sleeve is also excellent.

Conclusion: The Right Tool for the Job

Although standard sleeves are widely used in most scenarios, in complex engineering scenarios, more professional solutions are often needed to meet challenges. Our special sleeve series always adheres to the research and development concept of overcoming practical problems for customers - by integrating multiple material properties and combining innovative design elements such as zipper structure and hook and loop structure, it provides accurate solutions for typical problems such as electromagnetic interference (EMI), mechanical noise, and high-frequency vibration. When you encounter seemingly unsolvable problems during wiring, remember: general solutions may not be the best solutions. Special solutions based on professional technical accumulation and high performance are the key to breaking through bottlenecks.