The Difference Between Cable Conduit, Wrap, Sleeves and Tubing

2025-12-17 15:12In typical industrial production and maintenance scenarios, various cable protection devices may appear similar in appearance. However, the actual application scenarios and protective functions of these four types of products—cable conduits, cable wrap, cable sleeves, and Tubing—differ significantly, making product selection crucial. While an incorrect choice may provide temporary protection for the wiring harness, varying degrees of hidden dangers will arise over time due to changing seasons and unpredictable conditions. This results in wasted manpower, resources, and money, ultimately proving counterproductive. Choosing the right product is paramount.

The following content provides a very detailed analysis, helping you establish a clear distinction between the usage methods and selection criteria for these four products. This will allow you to select the most suitable cable protection sleeve for your needs in the shortest time and at the most reasonable price.

1.Cable Conduit — Corrugated conduit & PVC coated flexible steel conduit

As a high-strength cable protection solution, corrugated conduit includes PE/PP/PA corrugated conduit and PVC coated flexible steel conduit, offering exceptional pressure/impact resistance and environmental adaptability. Ideal for heavy-duty wiring, pressure-resistant needs, and neat/aesthetic wiring requirements.

Best for:

Automotive

Machinery

Industrial control systems

Outdoor/harsh environments

Key Features:

Reinforced corrugated structure delivers maximum protection.

Excellent crush resistance: Even pressure dispersion, with steel-core variants excelling in high-load scenarios.

Widely used in automotive wiring and industrial equipment: Resists heat, vibration, corrosion, and mechanical wear.

Suitable for vibration, friction, or frequent equipment movement. Choose PE/PP/PA material for flexibility/cost-effectiveness, or PVC coated flexible steel for robust, long-lasting protection in high-stress environments—both ensure safe, reliable cable protection.

2. Cable Wrap — Self Closing Wire Wrap

Best for:

Cable management

Office/electronic device wiring

wire bundles with frequent changes or upgrades

Self closing wire wrap tape has gained widespread market recognition due to its excellent flexibility and convenient installation. It can be directly wrapped around the surface of wires without cutting existing cables, making it particularly suitable for equipment maintenance, IT terminal installation, and the organization and tidying of audio and video cables.

Key Features:

Quick installation

Great for bundling multiple cables

Suitable for environments where cables need frequent adjustment

Provides abrasion protection

If your cables require ongoing modifications, cable wrap is the most convenient option.

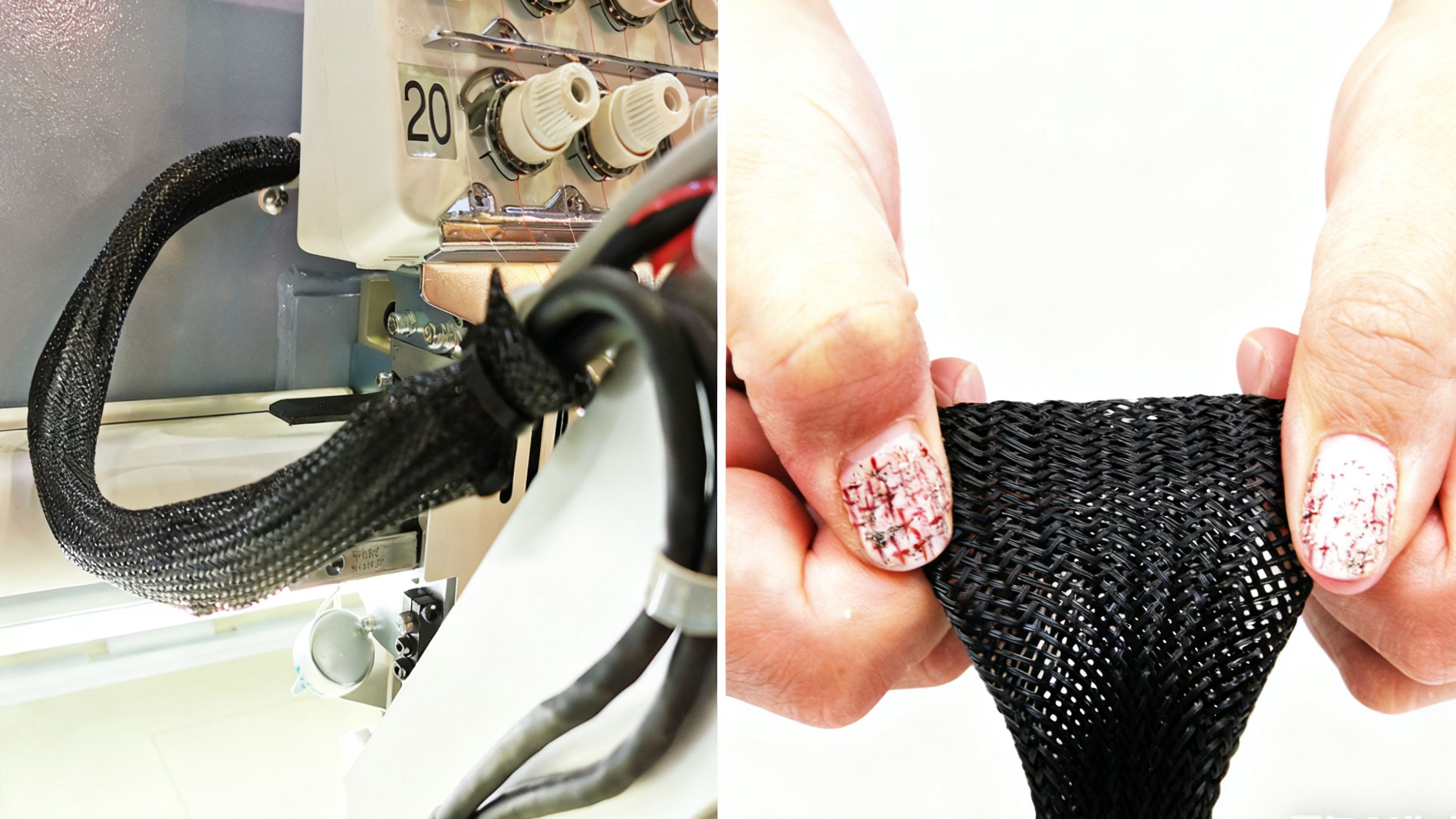

3.Cable Sleeve — PET expandable braided sleeving

Best for:

Automotive harnesses

Electronics

Home appliances

Industrial wiring

Heat-dissipating applications

PET expandable braided sleeving meets the abrasion protection requirements of various industrial fields, especially with its unique braided structure that allows it to expand to 1.5 times its original volume, facilitating the design and wrapping of wire harnesses and enabling it to easily pass over bulky connectors.

Key Advantages:

Lightweight and flexible

Good abrasion resistance

Professional look for wire harnesses

Expandable types fit irregular or multi-branch cables

Heat-resistant materials available for high-temperature environments

From the automotive and 3CE industries to the home appliance industry, cable conduits have always been one of the most commonly used solutions.

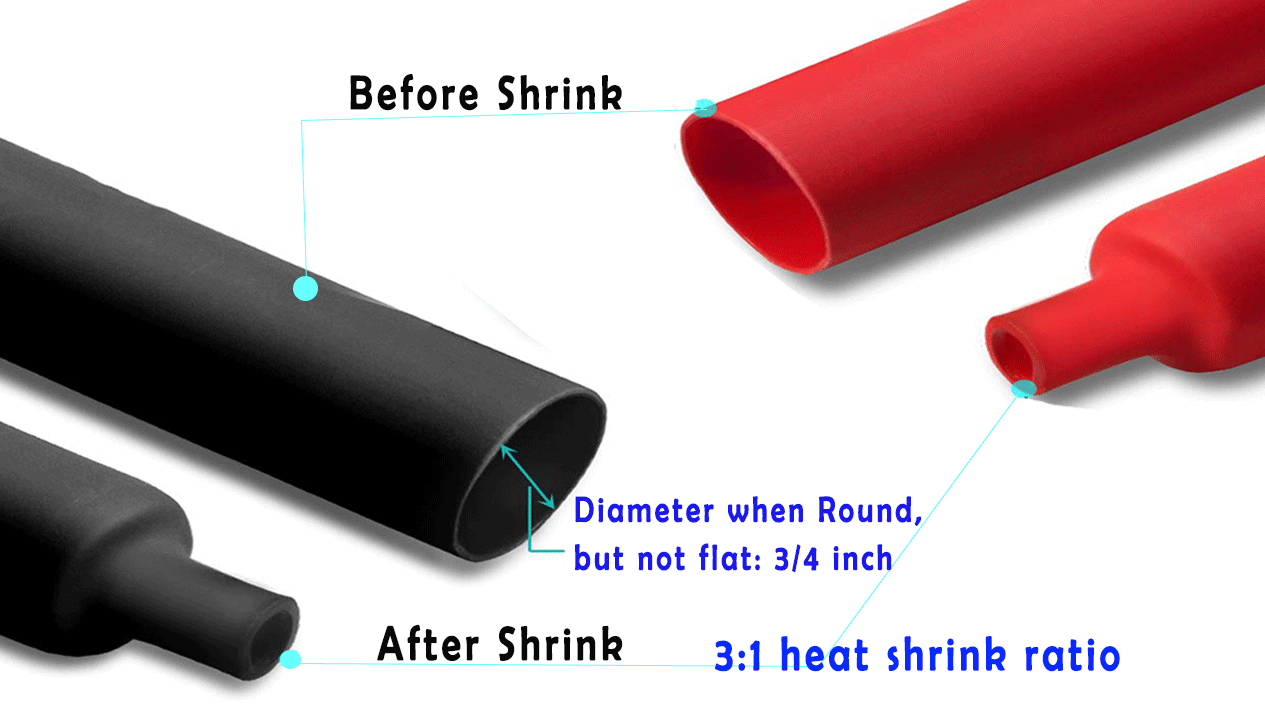

4. Cable Tubing —heat shrink tubing

Best for:

Electronics

LED lighting

Battery packs

Waterproof or dustproof applications

Heat shrink tubing is a new type of environmentally friendly, halogen-free, flame-retardant tubing. It is inexpensive and provides insulation protection for electronic and electrical components, exhibiting excellent performance in low-temperature shrinkage, flexibility, flame retardancy, insulation, and corrosion resistance. It is widely used to protect the surface of metal products from rusting and to provide insulation protection for electrical wires.

Typical Materials:

Heat-shrink tubing

Silicone tubing

PVC tubing

Key Features:

Excellent insulation

Good sealing capability

Heat-shrink tubing offers a tight, secure finish

If your project has extremely high requirements for neat and orderly construction, thermal insulation, or moisture-proof sealing, then choosing shrink heat tubing will be the best decision you can make.

How to Choose the Right Cable Protection Product?

We will provide the most suitable product based on the cable's environmental conditions, special requirements, and maintenance conditions, etc.

Application Scenario | Recommended Product | Key Benefit |

Heavy-duty protection | Conduit | Highest strength & durability |

Cable organization / Frequent changes | Wrap | Easy installation & adjustment |

General wire harnessing | Sleeves | Versatile, clean, professional |

Sealing / Heat resistance | Tubing | Tight protection & insulation |

Conclusion

Only by clearly understanding the purpose, function, properties, conditions, and specific protection scenarios of these conduits can we select the appropriate and safe products. Just as people differ from one another, so do conduits. Through their properties and applications, we can establish a complete cable management system that meets technical and practical needs and ensures safety.

FAQ

Q:What is a corrugated conduit?

The corrugated conduit is a thin wall corrugated tubing that is moisture-resistant and flame retardant. It is pliable such that it can be bent by hand and not threaded due to its corrugated shape.

Q:Is the self closing wire wrap easy to maintain after installation?

Yes.To facilitate the modification, reinstallation, maintenance, and repair of the internal protection wiring harness, we specifically adopted an open structure.

Q:Why can pet expandable braided sleeving accommodate wire harnesses of different diameters?

Because the braided structure of PET expandable braided sleeving allows it to expand to 1.5 times its original diameter, making it more suitable for wrapping wire harnesses and allowing it to easily pass through bulky connectors.

Q:How does the heat shrink tubing work?

The working principle of heat shrink tubing is that it "remembers" its expanded shape through a cross-linking reaction; when you apply heat , it shrinks tightly around the object, providing insulation, stress relief, and environmental sealing.