- Home

- >

- News

- >

- What is Cable Sleeving?

- >

What is Cable Sleeving?

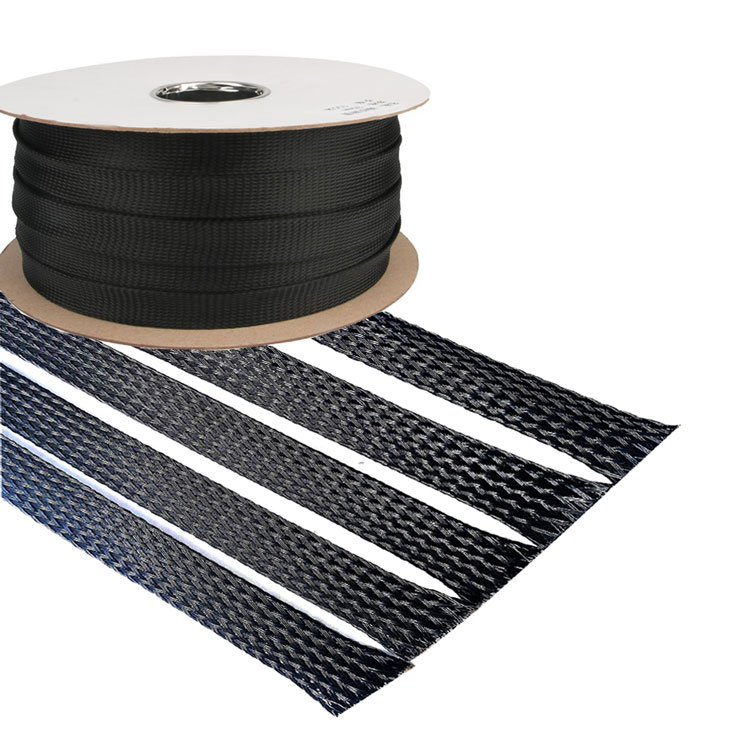

2024-06-24 16:38Cable sleeving is a protective cover used to organize, manage, and safeguard wires and cables. It is typically made from materials such as PET (polyethylene terephthalate), nylon, or other flexible, durable materials. Cable sleeving is available in various forms including braided sleeving, spiral wrap, and split loom tubing.

Types of Cable Sleeving

Braided Sleeving

Made of interwoven strands of material.

Offers excellent abrasion resistance and flexibility.

2.Spiral Wrap

A spirally cut tube that can be wrapped around cables.

Provides easy access for cable re-routing.

|  |

3.Split Loom Tubing

A corrugated tube with a slit down its length.

Ideal for easy installation and cable maintenance.

Importance of Using Cable Sleeving

Protection

Shields cables from physical damage, abrasion, and environmental factors such as moisture, chemicals, pet chewing and temperature variations.

2.Organization

Helps keep multiple cables bundled together neatly, reducing clutter and simplifying cable management.

3.Safety

Minimizes the risk of electrical fires by preventing short circuits and reducing wear on cable insulation.

4.Aesthetics

Enhances the visual appeal of cable installations by providing a clean, organized look.

6.Noise Reduction

Reduces cable vibration and noise, especially in automotive and industrial applications.

By utilizing cable sleeving, you can significantly enhance the lifespan, efficiency, and safety of your cable installations, making it an essential component in various applications .