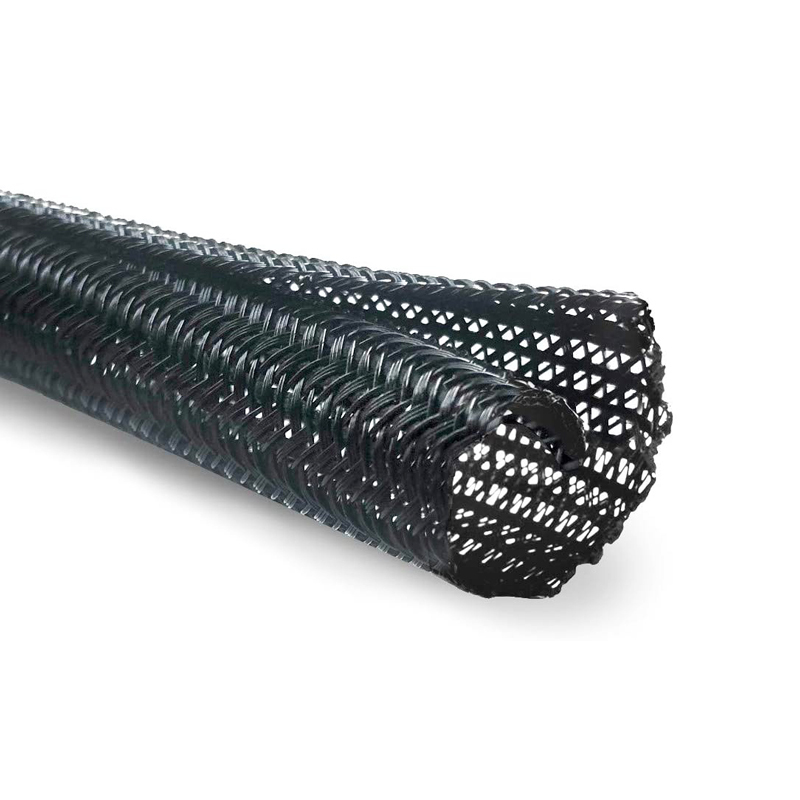

PET split braided sleeving

PET braided sleeving offers excellent heat dissipation, fire resistance, and wear resistance, making it an ideal choice for cable protection. The durable structure of PET braided sleeving ensures long-lasting performance, while its simple and convenient installation process makes it easy to apply to various cables and wires.

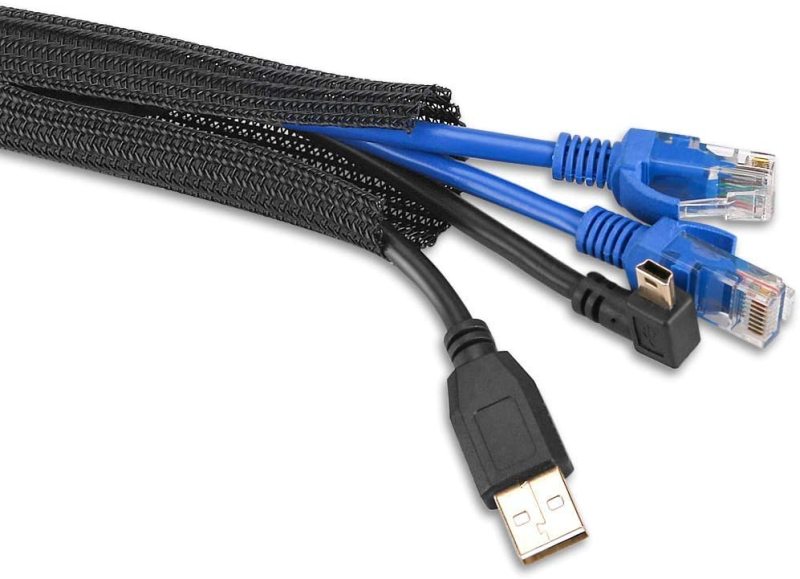

The open structure of PET braided sleeving facilitates easy reinstallation, maintenance, and repair of cables. This feature ensures that cables protected by PET braided sleeving remain accessible for future adjustments or replacements, offering greater flexibility in managing cable systems.

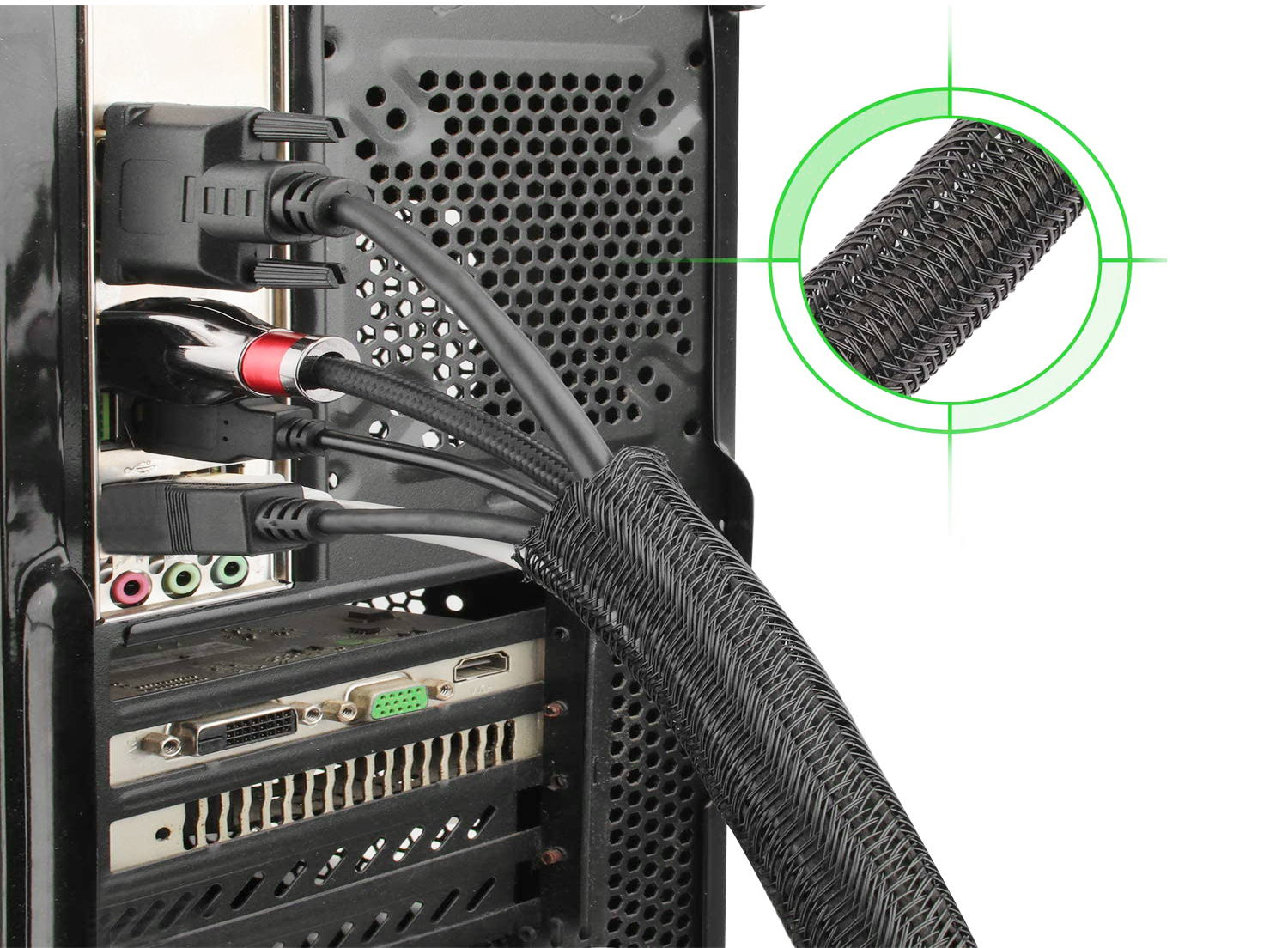

PET braided sleeving is widely used in critical applications such as high-speed rail, automobiles, automation equipment, and computer wiring, especially in environments where both protection and heat dissipation are essential. The robust properties of PET braided sleeving make it a reliable solution for protecting cables in these demanding environments.

- EKO

- China

- 7-15days

- 5000000Meters/Month

- Information

- Video

PET split braided sleeving Flexible Cable Protection & Management

PET (Polyethylene Terephthalate) split braided sleeving is a robust and flexible material designed to provide exceptional protection for cables and wiring. Made from synthetic fibers, PET braided sleeving acts as a shield against physical damage, including abrasions and cuts, while also offering some degree of defense against heat and chemicals. Below are the key features of the expandable sleeve:

Durability: PET split braided sleeving offers long-lasting protection for cables, ensuring they remain safeguarded even in tough conditions.

The benefits of combining expandable sleeves with PET braided cable sleeving include:

Adaptability: Expandable sleeves adjust to various cable sizes, providing a versatile, one-size-fits-all solution that simplifies cable management. This makes them ideal when handling cables of different diameters.

Hassle-Free Installation: Expandable braided sleeves can be effortlessly applied around cable bundles without requiring additional tools or complex procedures.

The advantages of using expandable sleeves alongside PET braided cable sleeving include:

Versatility: Expandable sleeves adapt to different cable sizes, offering a one-size-fits-all solution that simplifies cable management. This makes them a great choice when dealing with varying cable diameters.

Easy Installation: Expandable braided sleeves can be quickly installed around cable bundles without the need for additional tools or complicated processes.

Enhanced Aesthetics: When used in combination with PET braided sleeving, expandable sleeves provide a clean, professional look that keeps cables organized and visually appealing.

Cost-Effective: By choosing expandable braided sleeves, you reduce the need for multiple sizes of sleeving, cutting down on both costs and storage space.

Technical data

| Materrial | Polyester monofilament |

| Operating Temperature | -50℃~150℃ |

| Melt point | 240±10℃ |

| Flammability | VW-1 |

| Standard color | Black |

| Approval | RoHs |

| Certificate | UL,Halogen Fre |

| Cutting tool | Hot knife |

Data sheet

| Part No. | Inner diameter(d) | Max.bundle Dia | Packing(L) |

| BS-WS003 | 3.0 | 4 | 100m |

| BS-WS005 | 5.0 | 6 | 100m |

| BS-WS008 | 8.0 | 9 | 100m |

| BS-WS010 | 10.0 | 11 | 100m |

| BS-WS013 | 13.0 | 14 | 100m |

| BS-WS016 | 16.0 | 17 | 100m |

| BS-WS019 | 19.0 | 20 | 50m |

| BS-WS025 | 25.0 | 27 | 50m |

| BS-WS029 | 29.0 | 31 | 50m |

| BS-WS032 | 32.0 | 44 | 25m |

| BS-WS038 | 38.0 | 50 | 25m |

| BS-WS050 | 50.0 | 52 | 25m |

Whether you’re in the automotive, aerospace, electronics, or industrial sectors, the combination of PET braided sleeving and expandable sleeves can significantly improve the performance and longevity of your cable management systems. By choosing this highly effective solution, you can streamline your installation process, reduce costs, and ensure that your cables remain in optimal condition, no matter the environment or application.