How to choose the self-closed woven sleeving?

2021-10-13 17:09How to know the quality of self-closed woven sleeving?

Firstly, the most important is the material, when it reaches to a certain strength, the breaking method must be above the nominal value of the tensile force, whether it is broken or loose.That to say, the pulling force must be sufficient and each specification has its requirement.

Then, pay attention to the appearance quality. Lower quality self-closed woven sleeving will have defects such as edges, lack of material, scorching, monofilament, bubbles, deformation etc. Alough lower quality not affect the use, it will induce the potential threat of quality accidents.

Except for compressive and tensile tests, it is difficult to distinguish with the naked eye。Of course, people with experience can use the contrast method to distinguish, from the smoothness, fineness, color, and the content of various raw materials to compare. The good sleevings have smoothness, fineness, soft color.

The first step, see. See is the so-called observation with eyes. This is the most effective and intuitive method adopted by human beings when determining something. What you see is what you get and what you hear is false, and seeing is believing is a good proof. In view of the importance of seeing, carefully observe the self-winding textile sleeve you choose to see if the surface is smooth and round. If there is, it can be proved that it is a good product in the first step. If the appearance is rough everywhere There are potholes, it looks white as a whole.

This is caused by the addition of excessive calcium powder in the production process. Appropriate addition of calcium powder can effectively improve the hardness, but after excessive. The sleeving will become very brittle and lose its original flexibility. Such self-closed woven sleeving will inevitably have problems.

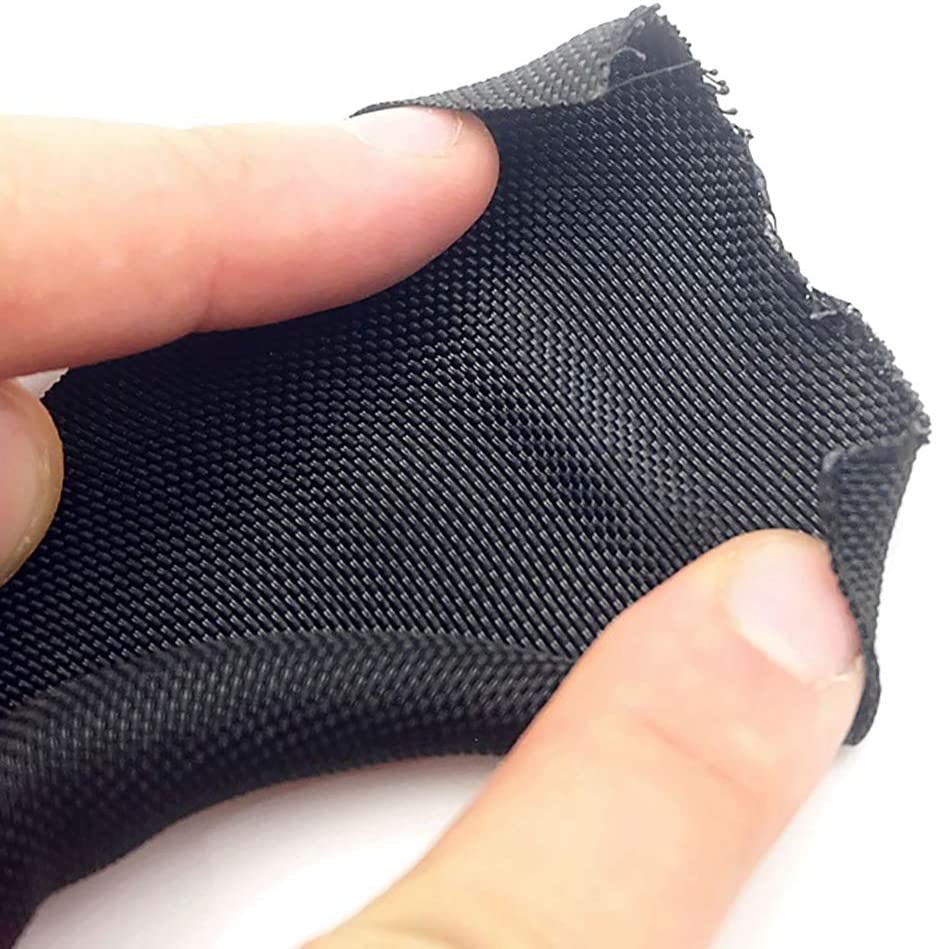

The second step, touch. Touch is to make various contacts with your hands to judge the problem. The quality of the self-closed woven sleeving directly affects the important property of the ring stiffness of the sleeving, so the most direct method is to do it by hand. Squeeze the wave crest. The good quality sleeving show that the wave crest is very strong and elastic. The lower quality sleeving is just the opposite. It can be easily squeezed by hand. Squash the wave crest into a depression.

The third step, smell, smell is to use the nose to smell the sleeving. From the smell to judge the quality of the sleeving, the good sleeving without peculiar smell, but the lower quality sleeving is smelly.

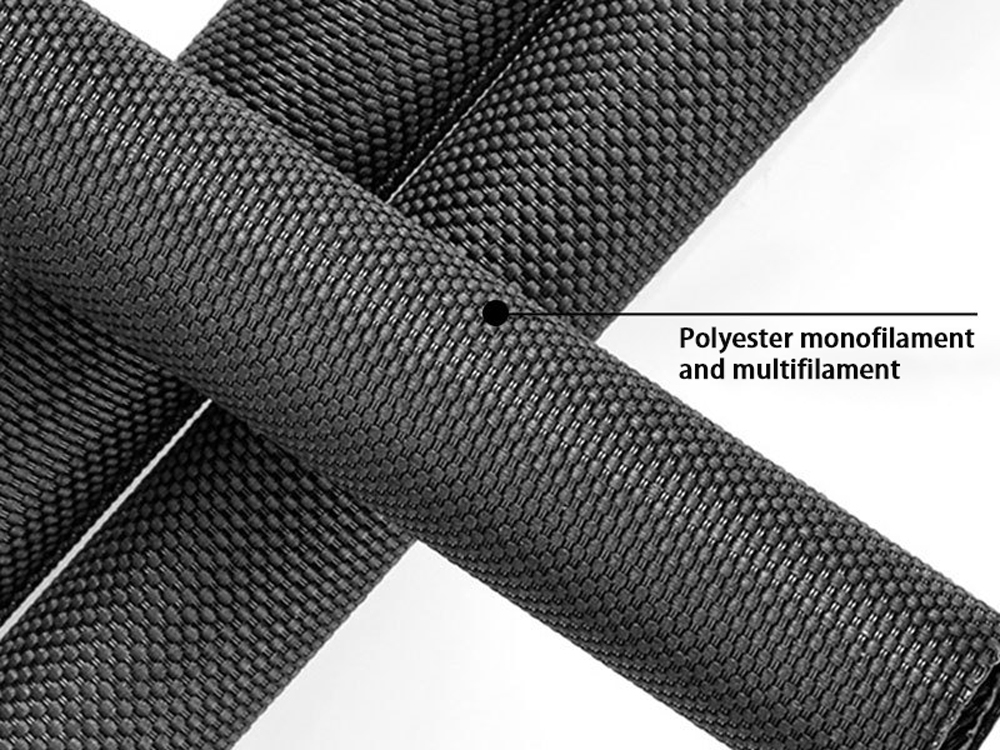

The fourth step, cutting, Cutting the sleeving to know the internal structure. It can we truly understand the quality of the self-winding textile casing. Then,we carefully observe the quality of the qualified sleeving when the cross section is taken. It will be found that the wall of the cross section is braided by polyester multifilament and polyester monofilament. A good sleeving observes that the wall thickness of the cross section is symmetrical, but the lower quality sleeving found that the thickness of the cross wall is different, and the thickness of the wave crest is also different.