Busbar Heat Shrink Tube

1.Avoid accidental injure to overhaul persons when they enter electriferous clearance by mistakes.

2.Provide excellent insulation performance to supply enquired flashover protection for the busbar system.

3.Solve the problem of insulating among busbars in bus trough.

- EKO

- Fujian

- 25-30 days

- 3000000 meters per month

- Information

- Video

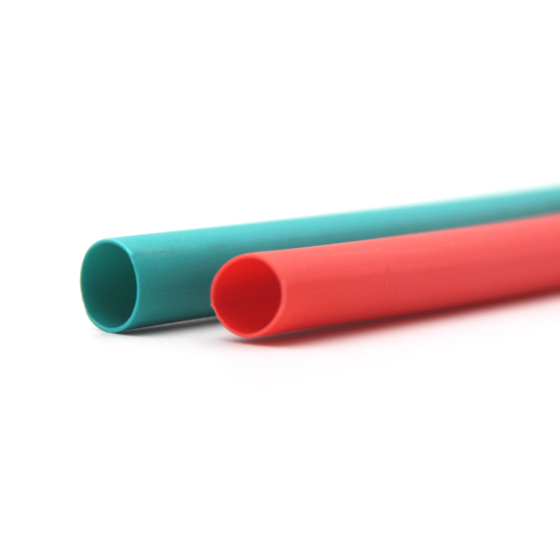

Non tracking crosslinked PE busbar heat shrink tube to protect against accidental flashove

QX-HV High voltage heat shrink busbar insulation tube, a kind of continuous tube shape material made of radiation cross-linked polyolefin, carry excellent insulating performance. Typical applications include insulation of electrical bus bar rated up to 1KV ~36KV voltage ratings, rectangular, square and round bus bars, inline bolted connections of rectangular bus bars, copper or aluminum bus bars, metal-clad switchgear, metal-enclosed bus bar, substation switchgear etc.

Technical data

Thermal Rating:125℃

Voltage Ratings:1KV~ 36kv

Continuous Operating Temperature:-40~125 ℃

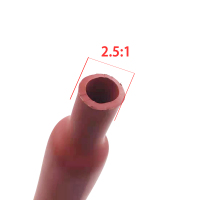

Shrink Ratio:2:1/2.5:1

Min. Shrink Temperature:84℃

Transport Package:Export Standard Cartons

Technical Performance

| Property | Typical Data | Test Method |

| Tensile strength | ≥14.0MPa | ASTM D 2671 |

| Elongation at break | ≥400% | ASTM D 2671 |

| Tensile strength after heat ageing | ≥8.0MPa | 130ºC×168h |

| Elongation after heat ageing | ≥400% | 130ºC×168h |

| Flammability(Oxygen index) | ≥28 | GB/T 2406 |

Data sheet

Size(mm) | As supplied(mm) I.D. | After recovered(mm) | Standard length | |

| Inner diameter d | Wall thickness w | (M/spool) | ||

| Φ25/10 | 25.0 | 10.0 | 3.5 | 15 |

| Φ30/12 | 30.0 | 12.0 | 3.6 | 15 |

| Φ40/16 | 40.0 | 16.0 | 3.6 | 15 |

| Φ50/20 | 50.0 | 20.0 | 3.6 | 15 |

| Φ65/25 | 65.0 | 25.0 | 3.6 | 15 |

| Φ75/30 | 75.0 | 30.0 | 3.7 | 15 |

| Φ85/35 | 85.0 | 35.0 | 3.7 | 15 |

| Φ100/40 | 100.0 | 40.0 | 3.7 | 15 |

| Φ120/50 | 120.0 | 50.0 | 3.8 | 15 |

| Φ150/60 | 150.0 | 60.0 | 3.8 | 15 |

| Φ175/75 | 175.0 | 75.0 | 3.8 | 15 |

Application

Busbar Heat Shrink Busbar Tube is widely used to avoid short circuit fault caused by small animals such as mice, snakes etc. Prevent busbar from chemical corrosion effected by strong acid, alkali, salt etc.