- Home

- >

- Products

- >

- Fiberglass Sleeving

- >

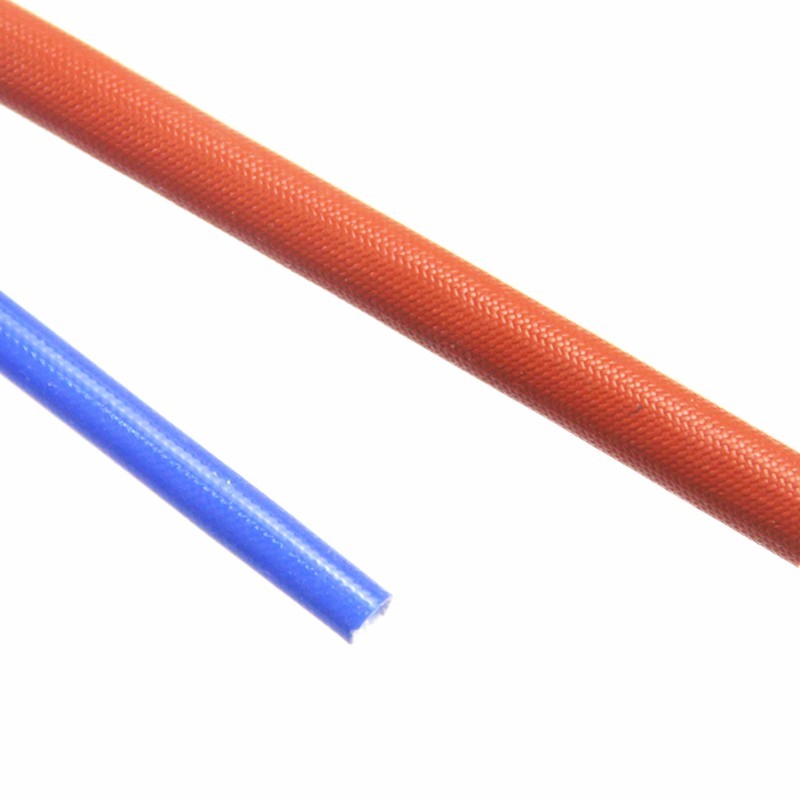

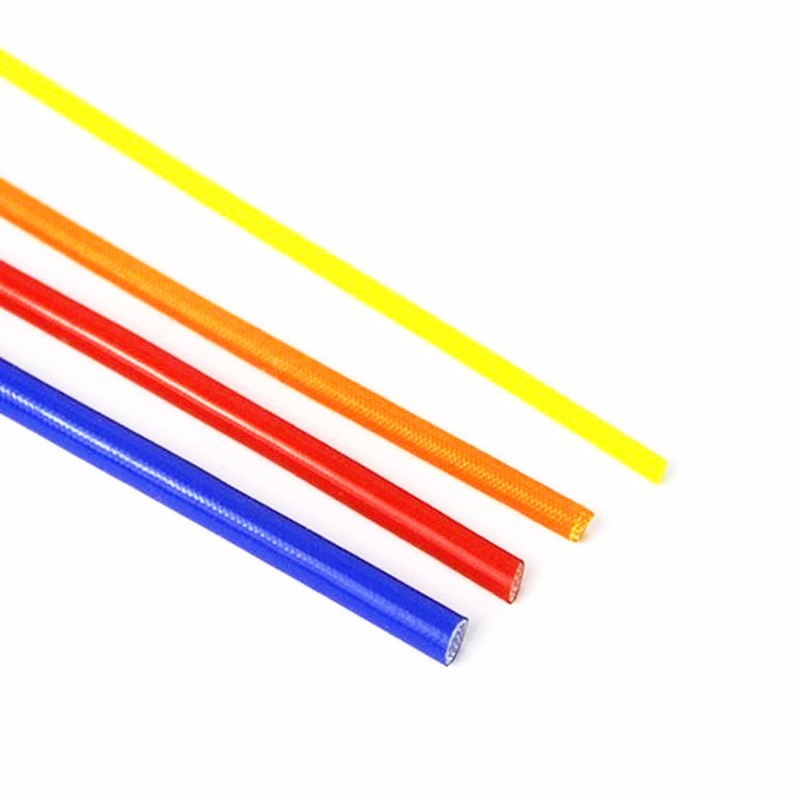

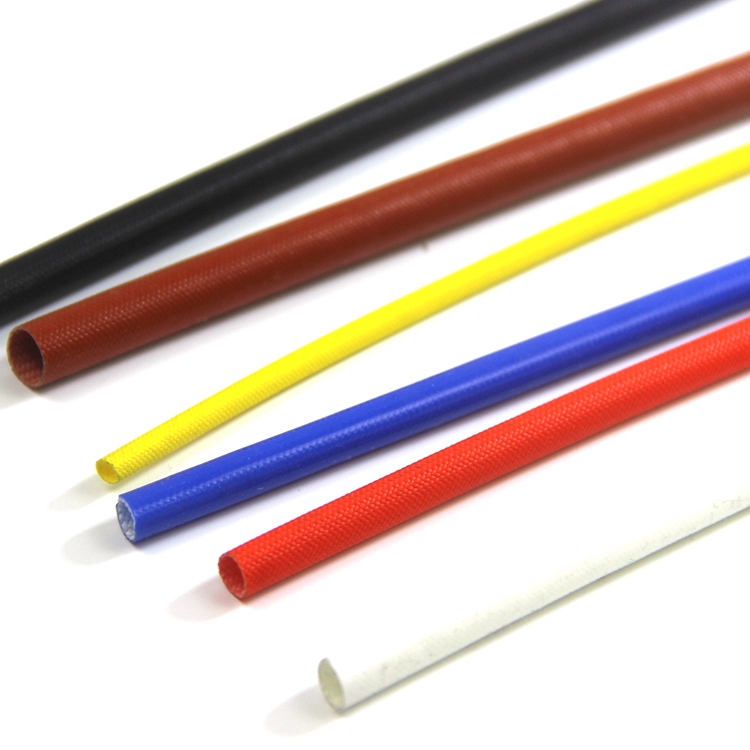

Fiberglass Sleeving

1.Tight weaving and full coverage

2.Economical and Easy to install

3.Non corrosive, fungas resistant

4.High temperature , aging resistant

5.Flexible and Soft

6.Self - extinguishing

7.High insulation

- EKO

- Fujian

- 15 days

- 1000000 meter/month

- Information

White Silicone Rubber coated Fiberglass sleeving to shed sparks and molten metal splash

Fiberglass sleeving is composed of a tightly braided, highly flexible, continuous filament E glass which has been heat-treated and saturated with an acrylic binder to reduce fraying when the sleeve is cut.

This protective braid is engineered to accommodate high temperature and low voltage applications such as commercial and home appliances, but the wide variety of diameters open the potential to many other industries.

Physical Properties

| Material | fiberglass |

| Coating material | silicone |

| Operating range | -60℃±200℃ |

| Breakdown volotage | 4.0kv/7.0kv |

| Flammability | VW-1 |

| Standard color | white/black |

| Certificate | UL,CSA,RoHS |

Datasheet

| Part No. | I.D.(mm) | Packaging |

| BS-FS-SC001 | 1.2 | 100M/ROLL |

| BS-FS-SC002 | 2.2 | 100M/ROLL |

| BS-FS-SC003 | 3.2 | 100M/ROLL |

| BS-FS-SC004 | 4.25 | 100M/ROLL |

| BS-FS-SC005 | 5.25 | 100M/ROLL |

| BS-FS-SC006 | 6.25 | 100M/ROLL |

| BS-FS-SC007 | 7.25 | 100M/ROLL |

| BS-FS-SC008 | 8.25 | 50M/ROLL |

| BS-FS-SC010 | 10.3 | 50M/ROLL |

| BS-FS-SC012 | 12.5 | 50M/ROLL |

Application

Fiberglass sleeve widely use for supplementary insulated or partially insulated conductors,

bus bars ,component, or aessemblies of electrical components etc.