PTFE Heat Shrink Tube

1.Specially designed for protecting applications in extreme electrical Chemical and thermal environment

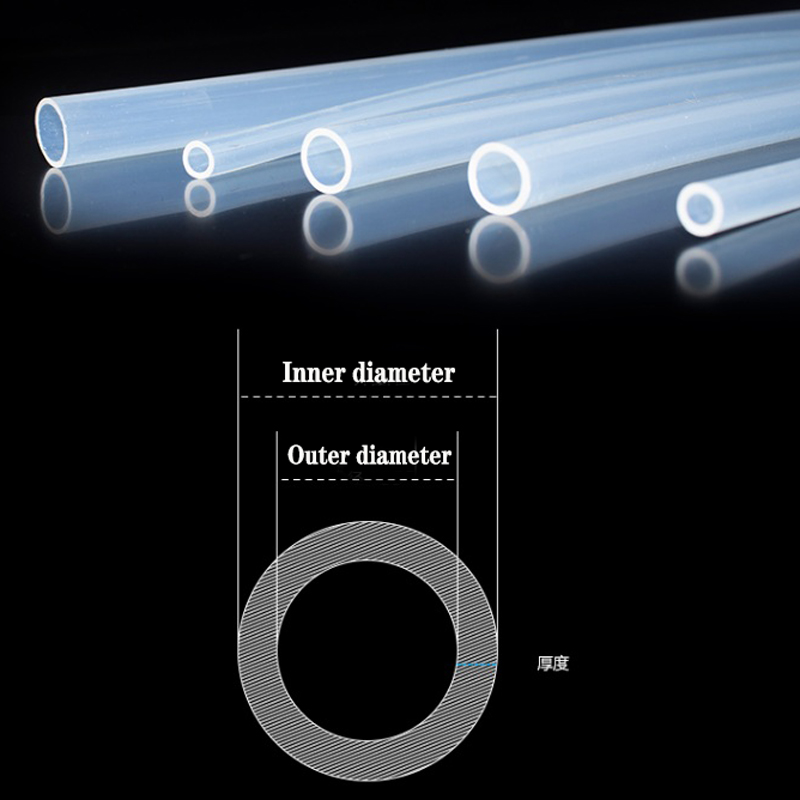

2.Medical Grade High Temperature 1.7: 1 Clear PTFE Heat Shrink Tube is applied imported polytetrafluoroethylene (PTFE). PTFE Heat Shrink Tube has excellent chemical resistance, heat resistance, weather and corrosion resistance.

It possesses excellent rigid and transparent. RoHS and Reach compliant.

- EKO

- Fujian

- 7-15days

- 2000000meters/month

- Information

Heat Shrink Cable transparent polyolefin heat shrink tubing shrinkage ratio is 4:1

Create a moisture-resistant seal in applications where temperatures reach up to 450° F.

An adhesive lining melts when the tubing is heated and bonds to the underlying surface, creating a water-resistant seal. Made of PTFE,

it also resists abrasion and chemicals. Choose tubing with a larger shrink ratio to create a tight seal over irregularly shaped objects.

Features & Benefits

1, Heat shrink ratio: 1.7:1, 4:1

2, High flame resistance, superior electrical-chemical properties.

3, Low friction coefficient.

4, RoHs compliant.

Technical data

| Solubility | ≥280℃ |

| Working Temperature | -80℃-260℃ |

| color | black,Transparent |

| Dielectric constant (*)50HZ | 2.1 |

| Rigidity | 85 |

| Copper corrosion | No corrosion |

| Antibiotic property, erosion resistance property | Excellent |

| Toughness (fold, bend, tear etc.) | Excellent |

| Tensile strength Mpa (kgf/cm) | 20.5 |

| Breakdown strength (kv/mm) | 30 |

| Appearance | Smooth, no visible fur and defects, no impurity |

| Axial shrinkage (diameter) (%) | ≥5% |

| Extensibility(%) | 200 |

| Combustibility | VW-1 |

| Resistance | Wear resistant, anti-acid and anti-virus,corona discharge, solvent resistance, etc |

| Environment | No hazardous to humans and environment |

Data sheet

PTPF heat shrinkable tube specification (1:7)

| Size mm | As supplied I.D. | As supplied W.T. | After recovery I.D. | After recovery W.T. | ||

| Thin Wall | Thick wall | Thin Wall | Thick wall | |||

| φ0.5 | 0.7±0.2 | 0.10±0.05 | 0.15±0.05 | ≤0.40 | 0.15±0.05 | 0.25±0.05 |

| φ1.0 | 1.0±0.2 | 0.10±0.05 | 0.15±0.05 | ≤0.50 | 0.15±0.05 | 0.25±0.05 |

| φ1.5 | 1.5±0.2 | 0.10±0.05 | 0.20±0.05 | ≤0.90 | 0.15±0.05 | 0.25±0.05 |

| φ2.0 | 2.0±0.2 | 0.10±0.05 | 0.20±0.05 | ≤1.30 | 0.15±0.05 | 0.30±0.05 |

| φ2.5 | 2.5±0.2 | 0.10±0.05 | 0.20±0.05 | ≤1.50 | 0.15±0.05 | 0.30±0.05 |

| φ3.0 | 3.0±0.2 | 0.15±0.05 | 0.20±0.05 | ≤1.80 | 0.20±0.05 | 0.30±0.05 |

| φ3.5 | 3.5±0.2 | 0.15±0.05 | 0.20±0.05 | ≤2.0 | 0.20±0.05 | 0.30±0.05 |

| φ3.8 | 3.5±0.2 | 0.15±0.05 | 0.20±0.05 | ≤2.0 | 0.20±0.05 | 0.30±0.05 |

| φ4.0 | 4.0±0.3 | 0.15±0.05 | 0.20±0.05 | ≤2.5 | 0.20±0.05 | 0.30±0.05 |

| φ4.5 | 4.5±0.3 | 0.15±0.05 | 0.20±0.05 | ≤2.8 | 0.20±0.05 | 0.30±0.05 |

| φ5.0 | 5.0±0.3 | 0.15±0.05 | 0.20±0.05 | ≤3.0 | 0.20±0.05 | 0.30±0.05 |

| φ6.0 | 6.0±0.3 | 0.15±0.05 | 0.25±0.05 | ≤3.8 | 0.25±0.05 | 0.38±0.05 |

| φ7.0 | 7.0±0.3 | 0.15±0.05 | 0.25±0.05 | ≤4.0 | 0.25±0.05 | 0.38±0.05 |

| φ8.0 | 8.0±0.3 | 0.15±0.05 | 0.25±0.05 | ≤4.8 | 0.25±0.05 | 0.38±0.05 |

| φ9.0 | 9.0±0.3 | 0.15±0.05 | 0.25±0.05 | ≤5.0 | 0.25±0.05 | 0.38±0.05 |

PTPF heat shrinkable tube specification (4:1)

| Size mm | As supplied | After recovery T.W. | After recovery ID | |

| thin | Thick | |||

| Φ1.5 | 1.5±0.2 | 0.05 | 0.1 | 0.40±0.1 |

| Φ2.0 | 2.0±0.2 | 0.05 | 0.12 | 0.50±0.1 |

| Φ3.0 | 3.0±0.2 | 0.05 | 0.12 | 0.7±0.1 |

| Φ4.5 | 4.5±0.2 | 0.05 | 0.12 | 1.2±0.1 |

| Φ6.0 | 6.0±0.2 | 0.12 | 0.12 | 1.5±0.1 |

| Φ7.0 | 7.0±0.3 | 0.12 | 0.15 | 2.8±0.1 |

Application

Widely used in electrical, computer, electro thermal, aerospace, military, and telecommunication etc.

Such as mini transformer, special sensor, artificial blood vessel.